The Complete Ice Machine Guide

Commercial Ice Machine Pricing Guide 2025

The Complete Ice Machine Buyer's Guide

Based on analysis of 701 ice machine sales with real market data

Average savings: 40-60% off retail prices🧊 Commercial Ice Machine Auction Prices

Ice machine pricing varies significantly based on configuration, production capacity, and ice type. Here's what 701 auction sales reveal about the current market:

Modular Ice Heads

$250-$1,500

Average: $578

Ice-making unit only, mounts on separate bin. Replacement flexibility and custom bin sizing.

Undercounter Complete

$200-$1,350

Average: $575

Integrated head and bin. Space-efficient for bars, cafes, small kitchens.

Nugget Ice Machines

$800-$3,800

Average: $1,617

Soft, chewable ice. 22% premium over cube ice. Healthcare, soda fountains, high-volume service.

Cube Ice Machines

$500-$4,100

Average: $1,327

Standard beverage ice. Most versatile, widest applications, largest selection at auction.

Ice Storage Bins

$150-$1,200

Average: $897

Insulated bins for modular heads. 100-600+ lb capacity options.

Key Market Insight:

Modular heads and complete undercounter units average nearly identical pricing ($578 vs $575), but offer different advantages. Modular systems provide upgrade flexibility and bin customization. Undercounter units save space and simplify installation. Your choice depends on available space and long-term flexibility needs, not price.

❄️ Ice Types: Applications & Performance

Different ice types serve different applications - choose based on your operation's needs

Full Cube Ice

Size: Approximately 1" x 1" dimensions

Best for: Slow dilution, maximum chill retention, high-end spirits and cocktails

Applications: Bars, restaurants, beverage service where drink integrity matters

Advantage: Melts slowest, provides longest cooling duration without diluting drinks

Half Cube Ice

Size: Half the dimension of full cube

Best for: Narrow-necked bottles (glass bottle sodas), blended drink applications, faster chilling

Applications: High-volume beverage service, smoothie shops, quick-service restaurants

Advantage: Smaller size requires less blender energy to break down, fits narrow containers

Dice Ice

Size: Slightly larger surface area than standard cube

Best for: Cocktails and spirits where slower dilution is critical

Applications: Premium bars, craft cocktail programs, high-end beverage service

Advantage: Larger melting surface area interfacing with beverage results in slower melt rate and less dilution

Nugget Ice (Sonic/Chewable Ice)

Nugget ice machines - the Chick-fil-A/Sonic ice that commands premium pricing

Why Nugget Ice Commands 22% Premium Pricing:

- Chewable without tooth damage: Frozen air pockets compress when bitten, reducing impact force

- Flavor absorption: Porous structure holds beverage liquid, creating flavor throughout the ice

- Reduced beverage volume needed: Customers feel satisfied with less total liquid because they're consuming flavor-locked ice

- Slower melt rate: Smaller atmospheric contact surface means lower heat input despite small ice size

- Higher profit margins: Full cup experience with less actual beverage - critical for fountain drinks

- Complex production: Specialized auger-based technology is costly to manufacture

Best applications: Soda fountains (McDonald's-style operations), healthcare (pediatric, maternity), high-volume beverage service where reducing product cost per customer matters

Flake Ice

Characteristics: Not structurally sound like cube ice, fast-forming, easy to blend

Best for: Blended drinks, seafood/meat displays, temperature-critical food presentation

Applications: Fishmongers, meat markets, smoothie operations, salad bars

Advantage: Small pieces quickly surround products for superior temperature control. As heat transfers from product to ice, flake melts into slurry that drains away, removing both heat and excess water for better "freshness" appearance

Gourmet Ice

Characteristics: Larger cubes with center hole or defined fracture line, crystal-clear appearance

Best for: Premium cocktails, single malt spirits, luxury beverage presentation

Applications: High-end bars, restaurants with open bar concepts, upscale hospitality

Advantage: Superior visual appeal, slower melt for expensive spirits, premium customer perception

| Ice Type | Auction Units | Avg. Price | Primary Use |

|---|---|---|---|

| Cube/Dice | 130 | $1,327 | General beverage service |

| Nugget | 33 | $1,617 | Soda fountains, healthcare, high-volume |

| Flake | 7 | $1,784 | Seafood display, blended drinks, specialty |

🔧 Modular Heads vs Complete Units: The Decision Tree

Modular Ice Heads

Average auction price: $578

Advantages:

- Replace ice maker without replacing bin

- Customize bin size to operation needs

- Upgrade production capacity later

- Standardized mounting hardware

- Some connect to remote condenser

Best for: Operations with space for separate components, those wanting long-term flexibility, or replacing failed ice makers while keeping functional bins

Complete Undercounter Units

Average auction price: $575

Advantages:

- Space-efficient integrated design

- Simpler installation process

- Self-contained operation

- Ideal for tight spaces

- ADA-compliant options available

Best for: Bars, small restaurants, cafes, operations prioritizing space efficiency and plug-and-play simplicity

Modular Head and Bin Compatibility

Modular heads come with built-in hardware to attach to standardized bins. Compatibility requires matching dimensions on at least 3 of 4 sides. If a 24" head mounts on a 48" bin, an insulated cover piece fills the remaining 24" opening to protect ice and maintain temperature.

Remote Condenser Units

Remote condenser relocates heat-producing components outdoors

Remote ice machines are air-cooled systems where the condenser unit is physically separated from the ice-making unit, connected by long refrigerant lines. The condenser (which produces heat and noise) is relocated outdoors or to a mechanical room, while the quiet ice maker stays in the kitchen.

Benefits of remote configuration:

- Quieter indoor environment - condenser noise stays outside

- Cooler kitchen - heat rejection happens away from cooking area

- Reduced AC strain - less heat load inside building

- Less wear on ice maker - cooler ambient temperature improves efficiency

Trade-offs: Higher installation cost due to refrigerant line running, requires outdoor space for condenser placement, must be specified as remote system (cannot convert standard units economically)

📊 Production Capacity vs Bin Size: The Math That Matters

The Peak Demand Formula

Calculate your bin size needs using this method:

- Determine production capacity per hour (daily capacity ÷ 24)

- Identify peak demand hours and total ice used during that period

- Find your highest single-hour demand during peak

- Double that highest hour for safety margin

Real-World Example:

Scenario: Bar open 2pm-2am, 500 lb/day ice machine

- Production per hour: 500 lbs ÷ 24 hours = 21 lbs/hour

- Peak period: 2pm-8pm (6 hours) = 50% of daily usage

- Peak total: 250 lbs during 6-hour window

- Average during peak: 250 ÷ 6 = 42 lbs/hour

- Highest single hour: 55-60 lbs (rush period)

- Safety margin: 60 × 2 = 120 lb bin minimum

Result: Despite 500 lb/day production, you need a 120 lb bin. The daily production is double the bin capacity because peak demand concentrates in 25% of operating hours.

Use Case Examples

| Operation Type | Production Priority | Bin Size Priority | Why |

|---|---|---|---|

| McDonald's/QSR | High | Medium | Constant demand all day - speed of production matters more than storage |

| Bar/Nightclub | High | High | Concentrated evening demand - need reserve capacity for rush |

| Seafood Market | Medium | High | Need large volume twice per shift for display refreshing |

| Hotel Breakfast | Medium | High | 6am-10am concentrated demand, minimal use rest of day |

| Office/Break Room | Low | Medium | Steady low usage, bin fills overnight for day use |

Production Capacity Pricing

Auction data shows clear price scaling with production capacity:

- Under 300 lbs/day: 83 units, avg $983

- 300-500 lbs/day: 54 units, avg $1,234

- 500-800 lbs/day: 20 units, avg $1,481

- 800-1200 lbs/day: 25 units, avg $2,378

- 1200+ lbs/day: 6 units, avg $2,560

🏆 Brand Comparison: Scotsman vs Manitowoc vs Hoshizaki

| Brand | Units Sold | Avg. Price | Reputation | Best For |

|---|---|---|---|---|

| Scotsman | 203 | $1,220 | ⭐⭐⭐⭐⭐ | Reliability, crystal-clear ice, strong undercounter lineup |

| Manitowoc | 163 | $651 | ⭐⭐⭐⭐⭐ | Smart features, versatility, wide model range for different needs |

| Hoshizaki | 134 | $643 | ⭐⭐⭐⭐⭐ | Heavy-duty, high-volume use, demanding environments |

| Ice-O-Matic | 21 | $590 | ⭐⭐⭐⭐ | Good value, reliable performance |

| Follett | 8 | $574 | ⭐⭐⭐⭐ | Specialty applications, niche markets |

Why Scotsman Commands 90% Premium at PCI Auctions:

Scotsman units average $1,220 compared to Manitowoc at $651 and Hoshizaki at $643. This significant premium is partly explained by consistent supply of brand-new scratch-and-dent Scotsman units from wholesale partners. These arrive in better condition than used units from competitors.

Important context: All three premium brands (Scotsman, Manitowoc, Hoshizaki) are quality commercial equipment. The price gap at PCI reflects supply chain factors, not inherent quality differences. Evaluate based on condition, features, and your specific needs rather than brand alone.

Brand Selection Guide

- Choose Scotsman for: Undercounter applications, reliability track record, crystal-clear ice production

- Choose Manitowoc for: Smart features and technology, versatile model selection, specific ice type needs

- Choose Hoshizaki for: Heavy-duty commercial use, high-volume production, durability in demanding environments

- Choose Ice-O-Matic/Follett for: Value-focused purchases, good performance at lower price points

💧 Air-Cooled vs Water-Cooled: Understanding the Trade-offs

| Factor | Air-Cooled (Industry Standard) | Water-Cooled |

|---|---|---|

| Cooling Method | Fans and ambient air remove heat | Water cools condenser directly |

| Installation | Simple - requires clearance for airflow | Complex - requires water supply and drain plumbing |

| Clearance Required | 6-8 inches on sides and back | Minimal - no airflow requirements |

| Performance in Heat | Reduced efficiency in hot environments | Superior performance regardless of ambient temperature |

| Operating Cost | Lower - electricity only | Higher - water usage + sewer charges + electricity |

| Noise Level | Moderate - fan noise | Quieter operation |

| Maintenance | Clean condenser coils periodically | Scale prevention in water lines |

When to Consider Each Type

Air-Cooled (95% of installations):

- Standard commercial kitchens with adequate clearance

- Operations prioritizing lower operating costs

- Areas without convenient water supply for cooling

- Most bar, restaurant, and food service applications

Water-Cooled (specialty applications):

- Extremely hot environments where air-cooling is inefficient

- Noise-sensitive installations requiring quietest operation

- Locations with inadequate clearance for air-cooled units

- Buildings with chiller systems providing closed-loop cooling water

🔍 Pre-Purchase Inspection Checklist

Critical Red Flag: Piercing Valves

Piercing valve (saddle valve) - WALK AWAY from any unit with these

If you see piercing valves on refrigerant lines, do not buy the unit. These indicate amateur refrigerant recharge without fixing the underlying leak. The problem still exists - the refrigerant will leak out again. Professional HVAC techs diagnose and repair leaks before recharging using proper vacuum and recovery procedures, not piercing valves.

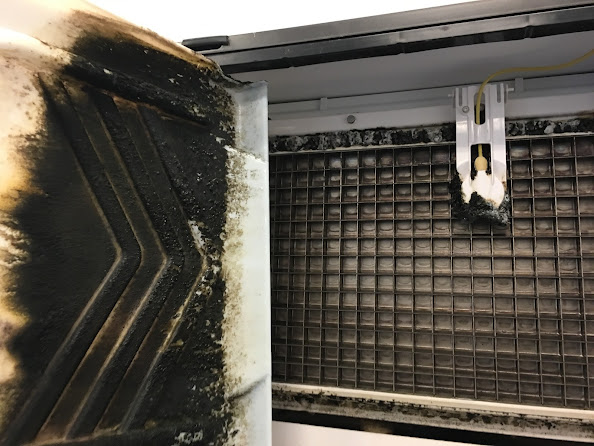

Evaporator Plate Inspection

Good condition - needs wiping but no damage

Bad condition - heavy scale, corrosion, neglected maintenance

Ask the seller to remove the front panel (typically 2 screws) to access the evaporator grid. This is the critical ice-forming component:

- Check for physical damage: Bent metal, separated components, cracked plates

- Test for scale buildup: Run fingernail across plate - sticky surface indicates mineral deposits

- Look for corrosion: Rust, pitting, or heavy oxidation indicates poor water quality or maintenance

- Verify alignment: Grid should be evenly positioned, not sagging or misaligned

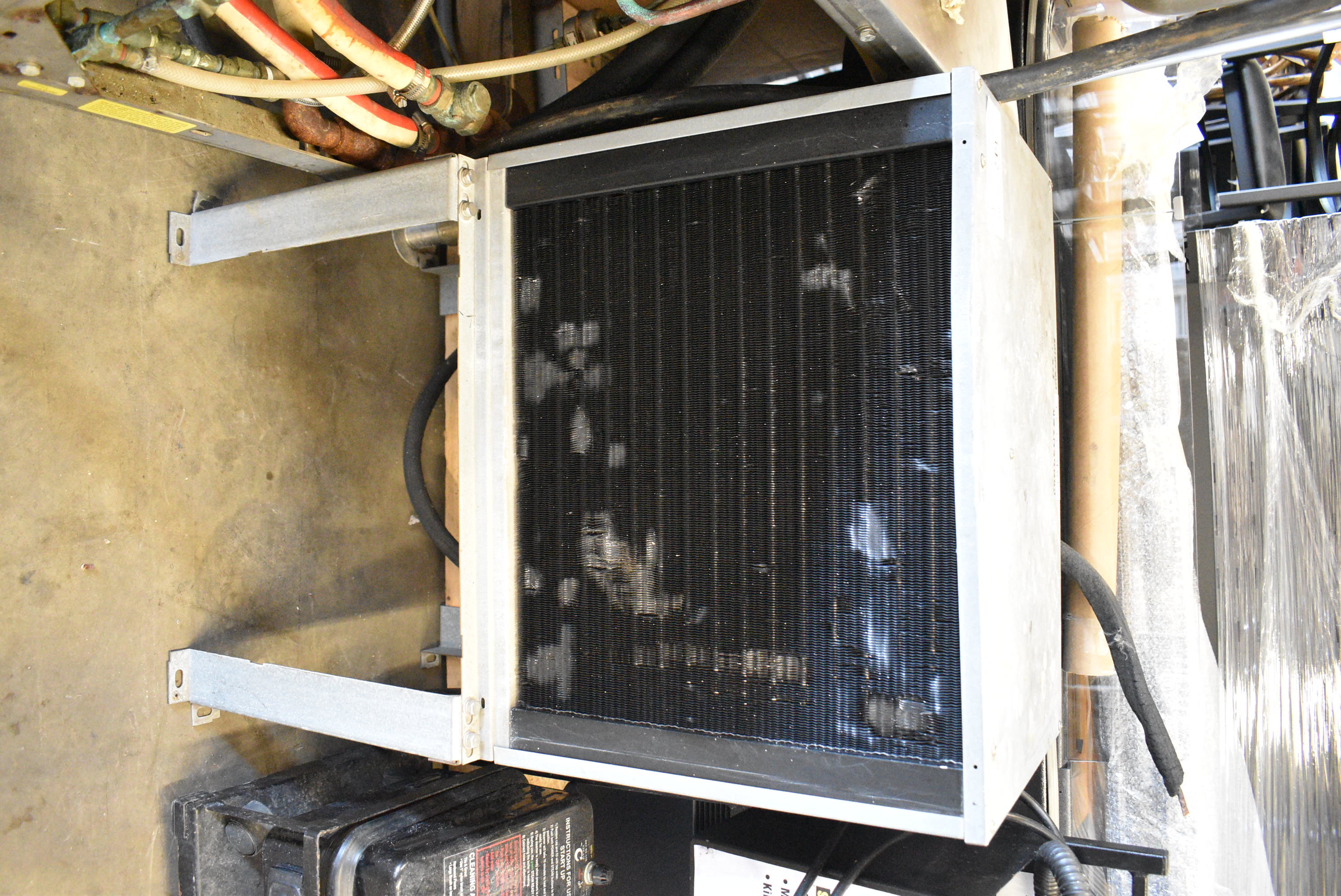

Compressor and Condenser Inspection

Compressor and condenser section - check for cleanliness and damage

- Inspect condenser coil for dirt, dust, or clogs that reduce efficiency

- Check compressor mounting - should be secure without excessive vibration wear

- Look for oil residue indicating refrigerant leaks

- Verify fan operation if able to power unit briefly

- Check electrical connections for corrosion or damage

Bin Condition Assessment

Bin interior - insulation should be intact without moisture damage

- Check exterior for dents, holes, rust, or corrosion

- Inspect interior for cracks in liner, mold, or slime buildup

- Verify insulation integrity - look for moisture damage or mold in insulation

- Test drain functionality - should flow freely

- Check door seals if applicable - should close tightly

Water Distribution System

- Check spray bars or nozzles for clogs or mineral buildup

- Verify water lines are intact without cracks or leaks

- Look for corrosion or scale in water pathways

- Ensure water pump (if equipped) shows no damage

Control Systems and Electrical

- Verify data plate information: production capacity, ice type, voltage, water pressure specs

- Check control panel for damage or corrosion

- Test that controls turn and function smoothly

- Look for burnt wiring or melted components

- Note any error codes if unit has digital controls

Signs of Poor Maintenance (Walk Away Signals)

- Mold or algae growth inside bin or on components

- Pink slime buildup (bacterial growth)

- Heavy scale deposits throughout system

- Rust or corrosion on internal parts

- Missing filtration system or never-changed filters

- Damaged or jury-rigged wiring

- Bent or damaged structural components

🚰 Installation Requirements: Water, Drainage, Electrical

Water Supply Requirements

- Dedicated water line: Machine controls on/off as needed

- Water pressure: 20-120 PSI required (verify specific unit specs)

- Line sizing: Varies by unit capacity - check manufacturer specs

- Shut-off valve: Install accessible valve for maintenance

Drainage Specifications (Critical)

Proper drainage setup - note air gap and slope requirements

Drainage Done Wrong (Common Mistake):

Most ice machines at auction have improper drainage installed. Unless your ice machine is a residential undercounter unit, the drain should ALWAYS be plumbed with 3/4-inch PVC with proper slope and air gap. If you see 1/2-inch PVC or flexible drain line without air gap, it's done incorrectly and will cause drainage issues.

Proper Commercial Ice Machine Drainage:

- Pipe size: 3/4-inch PVC minimum for both ice head drain and bin drain

- Slope requirement: 1/4-inch drop for every 1 foot of horizontal drain run

- Air gap requirement: Must maintain air gap between drain outlet and receiving drain

- Separate drains: Ice head and bin should drain separately if possible

- Floor drain or pump: Gravity-fed to floor drain ideal; drainage pump required if no floor drain available

Electrical Requirements

| Unit Size | Typical Voltage | Installation Notes |

|---|---|---|

| Small/Undercounter | 115V | Standard outlet, dedicated circuit recommended |

| Medium Production | 208-240V | Requires hardwiring, dedicated circuit |

| High Volume | 208-240V | Higher amperage, may need panel upgrade |

General electrical considerations:

- Higher voltage (208-240V) is more efficient to operate but requires professional installation

- Dedicated circuit prevents voltage drops and nuisance tripping

- Verify panel capacity before purchasing high-production units

- GFCI protection may be required by local code

Filtration System

Water filtration system - critical for ice quality and machine longevity

Filtration Is Not Optional

Filtration prevents: Sediment damage, hard water scale buildup, calcium deposits, poor taste/odor in ice, corrosion of internal components, premature equipment failure

Cost reality: Regular filter replacement is far cheaper than replacing an ice machine destroyed by poor water quality. Budget for filtration as part of ongoing operating expenses.

Old units without proper filtration show extensive calcium buildup, salt deposits, precipitate accumulation, and corrosion throughout the system. These problems compound over time and eventually destroy the machine.

Space and Clearance

Air-cooled units require:

- 6-8 inches clearance on sides and back for proper airflow

- Adequate room temperature - excessive heat reduces efficiency

- Keep away from heat sources (ovens, grills, direct sunlight)

- Ensure no obstructions blocking air intake or exhaust

General installation considerations:

- Level installation critical - use adjustable feet

- Access for maintenance - leave room to remove panels

- Proximity to point of use reduces ice handling labor

- Consider future service access when positioning

🧹 Maintenance Reality: Keeping Your Ice Machine Running

Monthly Cleaning Protocol (30-Minute Task)

Regular monthly cleaning extends machine life and ensures quality ice. The process is straightforward if done consistently - neglect makes it exponentially harder.

- Shut down machine and remove ice: Empty bin completely

- Remove face plate: Typically 2 screws provide access to grid and shroud

- Clean evaporator grid: Wipe down thoroughly, remove any scale or buildup

- Clean shroud and baffles: Remove mineral deposits and debris

- Rinse thoroughly: Ensure no cleaning residue remains

- Reassemble and restart: Allow sufficient time for bin to refill

Ongoing Maintenance Tasks

| Task | Frequency | Importance | DIY or Pro? |

|---|---|---|---|

| Clean evaporator grid/shroud | Monthly | Critical | DIY - 30 minutes |

| Replace water filter | Per manufacturer spec | Critical | DIY - 5 minutes |

| Clean condenser coil | Quarterly | High | DIY - 15 minutes |

| Inspect and clean bin | Monthly | High | DIY - 20 minutes |

| Check drainage flow | Monthly | Medium | DIY - 5 minutes |

| Professional deep clean | Annually | Recommended | Professional |

| Refrigerant system check | As needed | Critical if issues | EPA-certified tech only |

Filter Replacement

Water filtration is critical but maintenance details are equipment-specific. General guidance:

- Follow manufacturer recommendations for filter replacement interval

- Budget for regular filter costs as ongoing operating expense

- Hard water areas may require more frequent replacement

- Scale buildup on evaporator plate indicates inadequate filtration

💰 Hidden Costs & Total Cost of Ownership

Installation Costs

| Item | Typical Cost | Notes |

|---|---|---|

| Water line installation | $200-600 | DIY saves cost if handy; varies by distance |

| Drainage installation (proper 3/4" PVC) | $300-800 | Critical to do correctly; improper drainage causes ongoing issues |

| Drainage pump (if no floor drain) | $200-400 | Required when gravity drainage impossible |

| Electrical work (208-240V units) | $300-1,000 | Dedicated circuit, proper amperage, code compliance |

| Water filtration system | $100-400 | Essential - cheaper than replacing damaged machine |

| Initial cleaning/descaling | $100-300 | If purchasing used unit with visible buildup |

Ongoing Operating Costs

- Electricity: Varies by capacity and efficiency - higher for water-cooled due to water usage

- Water usage: Production water plus additional for water-cooled condensers

- Sewer charges: If water-cooled unit drains to sewer

- Filter replacements: Budget as regular expense

- Cleaning supplies: Monthly maintenance products

- Professional service: Annual deep clean or repairs as needed

Replacement Parts to Budget For

- Water filter cartridges: Regular replacement required

- Bin liner: If damaged, replace entire bin (more cost-effective than repair)

- Water distribution components: Spray bars, nozzles wear over time

- Control boards: Electronic controls can fail (expensive repair)

- Condenser fan motors: Air-cooled units experience motor wear

Refrigerant System Repairs: EPA Requirements

Critical: If refrigerant work is needed, hire EPA-certified technician. Venting refrigerant is illegal and environmentally harmful. Modern refrigerants can be flammable, adding safety concerns.

Red flag: If a unit has been "recharged" without proper leak repair, vacuum, and recovery procedures, the leak persists. The refrigerant will leak out again within days or weeks. Proper refrigerant work requires leak detection, repair, vacuum, and recharge - not just "topping off."

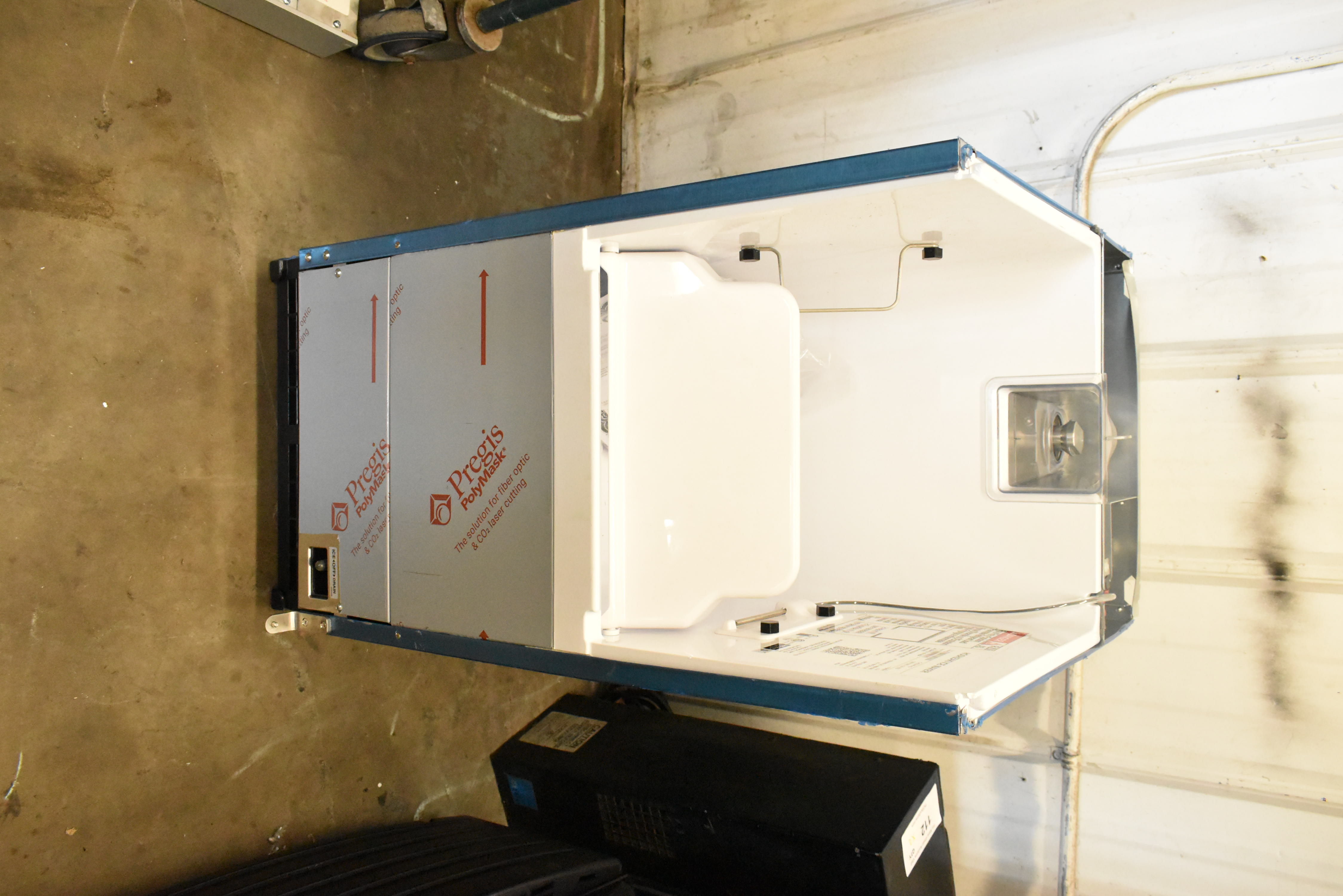

🏨 Special Applications: ADA Compliance & Hotel Systems

ADA-Compliant Undercounter Units

ADA-compliant unit - note lower height for wheelchair access

Front-access design for accessibility without assistance

ADA compliance features:

- Lower bin height for wheelchair access

- Front-access design eliminating need for assistance

- Controls positioned within accessible reach

- Clear floor space for wheelchair approach

Trade-offs:

- Reduced production capacity due to smaller evaporator in limited vertical space

- Smaller bin capacity constrained by height requirements

- Premium pricing for specialized design

When required: Public-facing ice access in commercial buildings, hotels, healthcare facilities, and any location where universal accessibility is mandated by local code.

Hotel Ice Systems with Carts

Hotel-style ice system with insulated cart - not exclusive to hotels

Large-capacity systems with insulated rolling carts solve ice transport challenges across multiple industries:

System advantages:

- High-volume production (often 1000+ lbs/day)

- Mobile ice delivery to multiple locations

- Insulated carts maintain ice quality during transport

- Centralized ice production reduces equipment duplication

- Efficient for large facilities with distributed ice needs

Applications beyond hotels:

- Hospitals and healthcare facilities (patient floors)

- Convention centers and event venues

- Large restaurants with multiple service areas

- Catering operations

- Institutional food service

Auction reality: Hotel-style systems appear occasionally and command premium pricing due to high capacity and specialty design. They're rare finds that suit specific high-volume, multi-location operations.

❓ Frequently Asked Questions

Should I buy a modular ice head or a complete undercounter unit?

Modular heads offer flexibility - you can replace the ice maker without replacing the bin, customize bin size to your needs, and upgrade capacity later. They average $578 at auction. Complete undercounter units are space-efficient, simpler to install, and self-contained, averaging $575 at auction. Choose modular if you have space and want flexibility; choose undercounter for compact installations or if you want plug-and-play simplicity.

What's the difference between cube, nugget, and flake ice?

Cube ice (including dice and half-cube) is standard for most beverage service, melts slowly, and provides maximum chill. Nugget ice is soft, chewable, and holds beverage flavor in its porous structure - ideal for soda fountains, healthcare, and high-volume operations where it reduces total beverage needed per customer. Flake ice is used for blended drinks, seafood/meat displays, and applications requiring fast cooling with maximum surface contact. Nugget machines command 22% premium pricing due to specialized auger-based technology.

How do I size an ice machine for my operation?

Calculate production capacity per hour, then multiply by your peak demand hours. Double your highest single-hour demand for safety margin. Example: 500 lb/day machine produces 21 lbs/hour. If peak demand is 6 hours at 50% total usage (250 lbs), that's 42 lbs/hour average but might spike to 60 lbs in one hour. Double that spike (120 lbs) for your bin size requirement. This ensures you have reserve capacity during rush periods even though daily production exceeds bin capacity.

Why do Scotsman ice machines cost more than other brands?

At PCI Auctions, Scotsman units average $1,220 compared to Manitowoc at $651 and Hoshizaki at $643. This 90% premium is partly due to consistent supply of brand-new scratch-and-dent Scotsman units from wholesale partners - these arrive in better condition than used competitors. Scotsman is known for reliability, crystal-clear ice production, and strong undercounter models. However, all three brands (Scotsman, Manitowoc, Hoshizaki) are quality commercial equipment - choice often comes down to condition and specific features needed.

What's the most important maintenance for ice machines?

Water filtration is critical - it prevents scale buildup, extends machine life, and ensures clean ice quality. Monthly cleaning of the evaporator grid, shroud, and baffles keeps ice quality high and prevents mold, slime, and mineral deposits. The face plate removes with typically just two screws for access. Cleaning takes 30 minutes if done regularly; neglected machines require hours of remediation. Always use proper drainage with 3/4-inch PVC, maintain air gap to prevent backflow, and ensure adequate air clearance (6-8 inches on sides and back).

Can I install an ice machine myself?

Yes, with proper preparation. Verify water line sizing, drainage specifications (3/4-inch PVC with 1/4-inch drop per foot), and electrical requirements before purchase. Have all parts and tools on hand. Key requirements: dedicated water line with 20-120 PSI pressure, proper drainage with air gap to prevent backflow, adequate electrical service (115V for small units, 208-240V for larger production), and 6-8 inches clearance for air-cooled units. If uncertain about refrigerant systems, hire an EPA-certified technician.

What are the red flags when inspecting used ice machines?

Walk away if you see piercing valves on refrigerant lines - this indicates amateur repair of a leak that likely wasn't fixed properly. Other red flags: damaged or separated evaporator plate, extensive scale buildup indicating poor maintenance, mold or slime in the bin or on components, compromised bin insulation with moisture damage, bent or corroded water distribution components, and heavily clogged condenser coils. Surface rust on exterior is cosmetic, but internal corrosion is serious.

What's the difference between air-cooled and water-cooled ice machines?

Air-cooled machines use fans and ambient air to remove heat - they're industry standard, simple to install, and require 6-8 inches clearance for airflow. Water-cooled machines use water to cool the condenser, offering superior performance in hot environments and quieter operation, but require significant water usage and additional plumbing for both supply and drain. Conversion between types isn't cost-effective. Remote condenser units relocate the heat-producing condenser outdoors, keeping kitchens cooler and quieter.

Do I need a water filtration system for my ice machine?

Yes, strongly recommended. Filtration prevents sediment, calcium, hard water deposits, and taste issues that degrade ice quality and damage internal components. Old units without filtration show buildup of calcium, salts, precipitates, and corrosion. Filter replacement is cheaper than premature ice machine replacement. Budget for regular filter changes as part of ongoing maintenance costs.

🧊 Current Ice Machine Inventory at PCI Auctions

We typically have 25-40 commercial ice machines available each week

Recent additions include Scotsman Prodigy series, Manitowoc modular heads, Hoshizaki undercounter units, and complete bar packages

View Current Ice Machines Call: 717-945-3986Set up email alerts for specific brands, ice types, or production capacities to get first access to new listings