The Complete Commercial Fryer Guide 2025

The Complete Commercial Fryer Guide 2025

Master fryer buying with real auction data from 1,000+ sales. Compare pressure fryers, ventless systems, filtration ROI, and brand value from America's premier equipment auction house.

Why This Guide Exists: The Menu Diversification Power of Fryers

Deep fryers are the ultimate menu diversification tool in commercial kitchens. From wings and fries to unexpected applications like bacon (5 minutes vs 20 in the oven) and crispy spinach garnishes for seafood dishes, fryers punch above their weight class in kitchen versatility. Appetizers drive check averages, and staples like fries, wings, mozzarella sticks, and poppers simply taste better fried.

At PCI Auctions, we move 600-900 lots weekly, including a diverse assortment of fryers ranging from standard single-bay units to multi-bay systems with built-in filtration, pressure fryers for QSR chicken concepts, ventless systems for non-traditional locations, and even cutting-edge automatic fryers. This guide analyzes over 1,000 fryer auction sales to give you data-backed pricing, insider buying tips, and the operational realities that separate smart investments from costly mistakes.

The $120 Question: Understanding Fryer Pricing Reality

| Fryer Type | Units Sold | Median Price | Typical Application |

|---|---|---|---|

| Pressure Fryer | 40 | $800 | QSR chicken concepts, fast-casual |

| Ventless System | 22 | $638 | Mall kiosks, historic buildings, non-hood locations |

| Floor Model (Gas) | 384 | $210 | Full-service restaurants, high-volume operations |

| Floor Model (Electric) | 331 | $91 | Locations without gas lines |

| Countertop | 270 | $75 | Food trucks, small cafes, limited fry menus |

| Accessories | 140 | $82 | Baskets, filtration systems, replacement parts |

Key Insight: Pressure fryers command a 4x premium over standard floor models ($800 vs $210) because they deliver shorter cook times, juicier meat with crispier breading, longer hold times, and lower oil consumption. Ventless systems justify their $638 median by eliminating hood installation costs that can exceed $15,000-$30,000.

Standard 2-bay gas floor fryer - The workhorse of commercial kitchens. Median auction price: $210

Fryer Types Deep Dive: Matching Equipment to Operation

Countertop Fryers: Entry-Level Volume

Countertop fryers range from 10-30 lbs oil capacity and are the most affordable entry point at $75 median. These units work well for food trucks with limited menu offerings, small cafes adding appetizers, or operations testing fry concepts before committing to floor models.

Avantco 2-bay countertop fryer - WebstaurantStore's house brand. Solid, serviceable units at accessible price points. Perfect for limited space applications.

Countertop vs Floor Decision: Beyond capacity, floor models offer superior recovery time, faster cooking speeds, easier cleaning access, and the ability to integrate with dedicated fry station workflow. In high-volume operations, fry stations warrant their own crew, refrigeration (often chef's base setups), and sometimes separate ticket printers because timing coordination is critical when entrees include "side of fries."

💡 Pro Tip: Chef's Base Integration

Countertop fryers maximize efficiency when mounted on refrigerated chef's base drawer systems. This setup provides cold storage directly beneath your fry station, streamlining workflow for proteins, frozen fries, and batters. Floor models with dry storage underneath waste prime real estate in compact kitchens.

Floor Model Fryers: The Kitchen Workhorse

Floor models dominate commercial operations with 40-100 lb oil capacity. Our auction data shows 406 floor units sold at $205 median for gas and $91 for electric. These are the backbone of full-service restaurants, fast-casual concepts, and any operation where fried food represents significant menu percentage.

Oil Capacity Standard Sizes:

- 30-40 lbs: Most common single or double bay configuration

- 50-70 lbs: High-volume operations, multiple bay systems

- 80-100 lbs: Large-scale institutional or stadium concessions

Pressure Fryers: The QSR Secret Weapon

Operating at 12 PSI, pressure fryers deliver measurable advantages that justify their $800 median auction price:

- Shorter Cook Times: 30-40% faster than open fryers

- Superior Quality: Sealed environment produces juicier meat with crispier breading

- Extended Hold Times: Perfect for QSR operations managing peak-and-valley demand

- Lower Oil Consumption: Sealed system reduces evaporation and breakdown

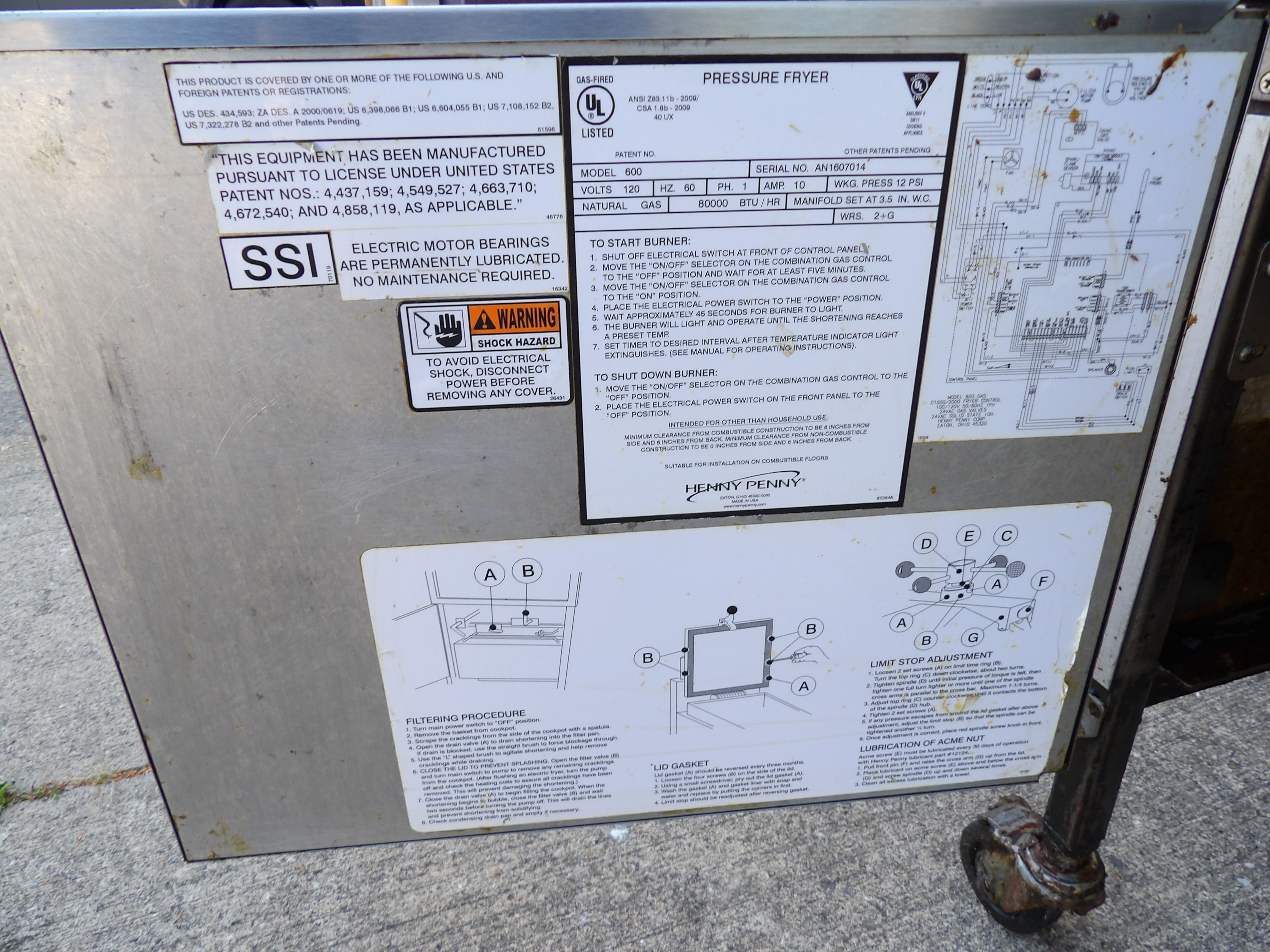

Standard pressure fryer - Notice the sealed lid mechanism. These units excel at chicken-focused concepts.

Henny Penny pressure fryer - The gold standard. Median auction price: $1,543. Built-in filtration and superior engineering justify the premium.

Ventless Fryers: The Location Game-Changer

At $638 median, ventless fryers cost more than standard floor models but eliminate the $15,000-$30,000 expense of commercial hood installation. These systems combine advanced filtration technology with integrated fire suppression, making them viable for:

- Mall and Airport Kiosks: Where traditional hoods are prohibited or impractical

- Historic Buildings: Preservation requirements prevent hood installation

- Non-Traditional Spaces: Offices, retail stores, entertainment venues

- Mobile Concepts: Food trucks and trailers with space/weight constraints

Giles ventless floor fryer - Modular system with separate hood and splash guard units. Washable filters require daily cleaning like traditional hood systems.

AutoFry ventless countertop - Complete system in a sealed enclosure. Perfect for tight spaces with no hood infrastructure.

💰 Ventless Filter Cost Reality

Annual Operating Costs:

- Countertop Ventless: $250/filter × 2-4 changes/year = $500-$1,000 annually

- Floor Model Ventless: Washable filters (like hood systems) require daily cleaning but no disposable replacement costs

ROI Calculation: If hood installation quotes exceed $15,000, ventless systems paying $500-$1,000/year in filters achieve payback in the first year while opening location possibilities impossible with traditional hoods.

Automatic Fryers: The Automation Future

AutoFry and similar brands represent cutting-edge kitchen automation with timer-based controls, digital temperature management, and automatic basket lift systems. These rarely appear at auction, but when they do, expect premium pricing reflecting their specialized technology.

Future Outlook: The next 5 years will see explosive growth in automated fry systems. Think of the automated hot dog robots now appearing in convenience stores - fryers are next. Standardized cooking times and temperatures make frying ideal for full automation, especially when combined with ventless technology for unconventional locations.

Brand Value Matrix: Where Your Money Goes

Our analysis of 738 actual fryers (excluding accessories) reveals a clear brand hierarchy based on median auction prices:

| Brand | Units Sold | Median Price | Market Position |

|---|---|---|---|

| Henny Penny | 30 | $1,543 | Super Premium - Industry gold standard |

| Perfect Fry | 8 | $1,525 | Super Premium - Ventless technology leader |

| Vulcan | 42 | $238 | Mid-Tier Reliable - Proven workhorse |

| Frymaster | 33 | $210 | Mid-Tier Reliable - Strong reputation |

| Pitco/Frialator | 108 | $205 | Mid-Tier Reliable - Most common premium brand |

| Imperial | 20 | $221 | Budget Tier - Solid performer |

| Dean | 19 | $155 | Budget Tier - Serviceable option |

| Avantco | 108 | $147 | Budget Tier - WebstaurantStore house brand, solid quality |

| Cecilware | 13 | $85 | Budget Tier - Bottom tier pricing |

| Unknown/Import | 347 | $91 | High Risk - Parts availability concerns |

Henny Penny 3-bay system with built-in filtration - Sold for $3,600 at auction. Premium engineering, integrated oil management, and legendary durability justify the investment for high-volume operations.

Gas vs Electric: The Fryer Reality

Unlike griddles where gas dominates, fryers present a more nuanced decision. Our auction data reveals surprising patterns:

Gas Fryers

Units Sold: 384

Median Price: $210

BTU Range: 90,000-115,000 (median: 105,000)

Advantages:

- Faster recovery times

- Lower operating costs in most markets

- Preferred for high-volume operations

- Food truck essential (efficiency matters)

Electric Fryers

Units Sold: 331

Median Price: $91 overall / $222 floor models

Voltage: Most require 208-240V (not standard 120V)

Advantages:

- Viable where gas lines unavailable

- Floor models perform competitively

- Simpler installation in some locations

- Universal infrastructure (every location has electric)

Decision Framework:

- Food Trucks: Gas only. Efficiency and BTU recovery are non-negotiable.

- High Volume (150+ covers/day): Gas preferred for recovery speed during rush periods.

- No Gas Available: Electric floor models work fine. Don't compromise location for gas access.

- Limited Fry Menu: Electric countertop adequate for appetizer-only programs.

- Countertop Applications: 115V electric often sufficient for low-volume operations.

Gas connection detail - Natural gas vs LP conversion is straightforward on most fryers. Orifices are exposed and easily accessible, unlike some griddle models.

💡 Pro Tip: Natural Gas to LP Conversion

Gas fryers typically ship configured for natural gas but convert easily to propane (LP). The conversion process is simpler than griddles because fryer orifices are exposed and accessible. Always verify gas type before bidding, but don't let NAT/LP configuration eliminate otherwise perfect units. Conversion kits are inexpensive and installation is straightforward for qualified technicians. This opens up auction opportunities other bidders overlook.

BTU Requirements: Recovery Time Reality

Fryer BTU ratings matter most when cooking frozen products or managing rush periods. Our data shows typical ranges:

- 40,000-60,000 BTU: Countertop units, limited production

- 90,000-120,000 BTU: Standard floor models (median: 105,000 BTU)

- 135,000-150,000 BTU: High-output single or double bay systems

- 150,000-255,000 BTU: Multi-bay banks (3-5 wells) or pressure systems

Equipment specification plate showing BTU rating and gas type. Always photograph or record these specs during in-person inspections.

Recovery Time Impact: When you drop frozen product into hot oil, temperature plummets. Higher BTU units return to cooking temperature faster, maintaining throughput during rush periods. Frozen fries, wings, and breaded items create the most dramatic temperature drops. Get as high BTU as your gas lines can accommodate - this single specification determines your kitchen's ability to handle volume without quality degradation.

The Filtration ROI: Daily Operations vs Long-Term Savings

Our auction data reveals a dramatic pricing premium for built-in filtration: units with integrated systems median at $900 versus $130 for standard fryers (6.9x multiplier). This premium reflects both the mechanical complexity and the operational value of proper oil management.

Filtration System Types

Built-In Filtration

Typically found on 3-5 bay floor systems where plumbing connects multiple wells to a central filtration pump. Oil flows through particle filters and returns to the same bay.

Auction Premium: $900 median

Best For: High-volume operations, multi-bay installations

External Filtration

Portable cart-based systems or hookup-ready fryers that connect to mobile filtration units. Oil is pumped out, filtered, and returned.

Typical Cost: $125-$400 for mobile units

Best For: Single or double bay operations, flexibility across multiple fryers

No Filtration

Manual oil changes only. "Use it till it's dead" approach creates bitter taste, degraded frying performance, and lower food quality.

Auction Price: $130 median

Reality: False economy - oil replacement costs dwarf equipment savings

Portable fryer filtration system - External filtration provides flexibility to service multiple units. Daily filtering extends oil life significantly.

💰 Oil Filtration ROI Calculator

Scenario: 40 lb capacity fryer, moderate volume restaurant

Without Filtration:

- Oil change frequency: Every 3-5 days

- Weekly cost: 40 lbs × $0.15/lb × 2 changes = $12/week = $624/year

- Food quality: Degrades daily, customers taste the difference

With Daily Filtration:

- Oil change frequency: Every 7-10 days (2x+ lifespan)

- Weekly cost: 40 lbs × $0.15/lb × 1 change = $6/week = $312/year

- Annual savings: $312 saved

- Food quality: Consistent, customers notice better flavor

Payback Period: If a filtration system (built-in or external) adds $300-400 to equipment cost, ROI achieved in 12-18 months through oil savings alone. Factor in improved food quality, customer satisfaction, and reduced labor (no daily oil changes), and filtration becomes non-negotiable for any operation serving fried food 5+ days weekly.

Filtration Reality in Auction Listings

Only 17 of 738 fryers in our data explicitly mentioned filtration. This scarcity occurs because:

- External Systems: Sold separately or already removed from units

- Missing Components: Filtration tray, cart, or plumbing missing from otherwise filtration-ready fryers

- Description Omissions: Sellers may not mention filtration capabilities in listings

Pre-Auction Inspection Critical: For units advertising filtration, verify the filtration tray or cart slides smoothly, the filtration pipe mounts properly, and the filter valve closes completely. Test with small amounts of water before attempting oil transfer. Water cleanup is manageable; oil spills are catastrophic and expensive.

Capacity and Bay Sizing: Matching Volume to Equipment

Fryer sizing isn't about oil capacity alone—it's about matching portion sizes to basket capacity while maintaining proper oil temperature and avoiding overloading.

The Wing Math Example

In a standard fryer basket, maximum capacity is 16-18 wings depending on size. Drop two full baskets simultaneously and oil temperature crashes. The better approach:

- Limit to 12 wings per basket across multiple units

- Reduce temperature drop by not overwhelming oil volume

- Faster return to cooking temp = shorter overall production time

- Higher throughput achieved by NOT maxing out individual fryers

This is why busy wing concepts run 3-4 double bay fryers instead of one massive 5-bay system—distributed load management beats centralized capacity.

Bay Count Auction Reality

| Bay Configuration | Units Sold | Median Price | Typical Use Case |

|---|---|---|---|

| Single Bay | 20 | $30 | Countertop, minimal fry menu |

| Double Bay (2) | 115 | $99 | Most common configuration - versatile |

| Triple Bay (3) | 5 | $2,004 | High volume, often includes filtration |

| Quad Bay (4) | 4 | $2,287 | Institutional, stadium, large operations |

Oil Flavor Separation Strategy

Beyond volume considerations, savvy operators dedicate bays to specific products:

- Bay 1: Fries and potatoes only (maintain neutral flavor)

- Bay 2: Breaded proteins (chicken, fish) that won't contaminate other items

- Bay 3: Mixed apps and specialty items

When fries taste like burnt fish because everything shares the same oil, customers notice immediately. Multiple bays aren't luxury—they're quality control.

Standard fry basket - Most common configuration for fries, wings, and general fried items.

Taco Fry Basket

Specialized basket for forming crispy taco shells. Mexican concepts frying their own tortilla shells create significant cost savings vs purchasing pre-fried shells while ensuring freshness.

Taco Salad Shell Basket

Bowl-shaped basket creates edible salad vessels. High-margin item (flour tortilla costs ~$0.15, sells as entree for $8-12) demonstrates fryer ROI beyond standard fry applications.

Control Systems: Digital vs Analog

Fryer control sophistication ranges from basic analog thermostats to sophisticated digital systems with programmable presets. Our auction data doesn't price this out separately, but operational differences matter:

Digital control panel - Programmable temperature presets, timer integration, and precise temperature management. More control, more things to break.

Analog thermostat control - Simple, reliable, nothing to program. Less precision, fewer failure points. For standard applications (350°F fries, 375°F chicken), analog suffices.

Analog Controls

Advantages:

- Fewer components to fail

- Easy staff training

- Lower repair costs

- Perfectly adequate for standard applications

Limitations:

- Less precise temperature control

- No programmable presets

- Manual timer management

Digital Controls

Advantages:

- Precise temperature management

- Programmable product presets

- Integrated timers and alarms

- Better for complex menus

Limitations:

- More expensive to repair

- Electronic components can fail

- Requires tech-savvy staff

Buying Strategy: If your menu consists of standard fried items (fries, wings, breaded apps) all cooked at similar temperatures, analog controls work perfectly fine. Digital systems shine when running diverse products requiring precise temperature variations—specialty proteins, donuts, unique batters. Don't pay premium for features you won't use.

Menu Diversification: Beyond Fries and Wings

Fryers deliver exceptional ROI because they enable menu expansion without adding significant kitchen complexity. Consider these unexpected applications operators successfully leverage:

Speed and Efficiency Plays

- Bacon: 5 minutes fried vs 20 minutes baked. Result is curly but perfect for salad toppings, burger crumbles, and applications where presentation matters less than speed. Bistros and diners use this extensively.

- Crispy Spinach: Fresh spinach dropped until crisp creates stunning garnish for seafood dishes. Fine dining application, minimal cost, impressive presentation.

- Tortilla Chips: Mexican concepts frying their own chips control freshness and cost. Bulk tortillas cut into triangles = $0.10/serving vs $0.40+ for bagged chips.

- Taco Salad Shells: Flour tortilla ($0.15) becomes edible bowl for $8-12 entree. High-margin item requiring only specialized basket.

High-Margin Opportunities

- Funnel Cake: Low ingredient cost, high perceived value, minimal prep. Food trucks and concessions leverage this heavily.

- Donuts: Made-to-order donuts command premium pricing. Small cafes adding donut programs see significant morning revenue boost.

- Fried Pickles/Specialty Apps: Trendy appetizers with 75%+ margins. Same fryer, different batter, premium check average.

The Appetizer Effect

Industry data consistently shows appetizers increase overall check averages by 20-35%. A table ordering mozzarella sticks ($8) while waiting for entrees adds pure profit—the fryer runs regardless, marginal cost is minimal, and customer satisfaction improves (eating while waiting beats staring at menus).

Fryers punch above their weight class in most kitchens. The versatility, speed, and margin contribution make them arguably the highest-ROI equipment investment after core cooking appliances.

Maintenance Reality: Daily, Weekly, and Deep-Clean Protocols

Daily Operations

- Filtration (if equipped): Run oil through filtration system end of day. 10-15 minutes prevents next-day quality issues.

- Vat Cleaning: Remove baskets, brush down interior walls, clear drain valve of particulate.

- Temperature Verification: Check thermostats reading accurately using external thermometer. Drift causes quality issues.

- Basket Cleaning: Soak in degreaser, wire brush caked buildup. Clean baskets fry better.

Weekly Maintenance

- Full Vat Cleaning: Drain completely, scrub all surfaces with commercial degreaser. Remove caked carbon buildup from heating elements or tubes.

- Oil Evaluation: Even with filtration, oil degrades. Perform sensory tests (color, smell, foam formation). Replace when quality drops regardless of time since last change.

- Gas Burner Inspection: Check pilot lights, flame pattern, ensure blue flame (yellow indicates incomplete combustion).

Periodic Deep Maintenance

- Boil-Out (Monthly-Quarterly): Fill vat with water and commercial fryer cleaner, run at temperature to dissolve caked carbon. Drain, rinse thoroughly, dry completely before adding oil.

- Thermostat Calibration: Professional calibration annually prevents temperature drift causing inconsistent results.

- Preventive Inspections: Gas connections, electrical components, filtration pump (if equipped), structural integrity of vat.

Pre-cleaning condition - This unit looks rough but requires only degreasing and elbow grease. Greasy exteriors at auction often hide perfectly functional equipment. Don't let cosmetics scare you away from mechanical soundness.

💡 Pro Tip: The Greasy Unit Opportunity

Fryers covered in grease at auction look terrible and scare off casual bidders, creating buying opportunities for informed operators. Heavy grease buildup requires effort to clean but says nothing about mechanical condition. Focus inspection on internal components (burners, thermostats, valves, vat integrity). A $200 degreaser bill and weekend cleaning session can transform $150 auction fryer into $800 operational unit. The effort filters competition.

Wear Components and Lifespan

Gas fryers are remarkably simple mechanically. The primary wear component requiring replacement is the thermostat. Unlike complex equipment with proprietary parts, fryer thermostats are standardized and inexpensive ($50-150). With proper maintenance, quality fryers deliver 15-20+ years service life.

Parts Availability: Major brands (Pitco, Frymaster, Vulcan, Henny Penny) maintain extensive parts networks. Unknown import brands may present challenges sourcing replacement components. Factor this into purchase decisions—saving $100 upfront costs thousands when critical component fails and no replacement exists.

Pre-Auction Inspection Checklist

If auction allows in-person inspection, focus on these fryer-specific evaluation points:

Visual Inspection (No Power Required)

- Vat Integrity: Inspect for cracks, warping, excessive pitting from acid degradation. Minor surface rust acceptable; structural damage is not.

- Drain Valve: Open and close multiple times. Should move smoothly with complete seal when closed. Leaking valves = oil everywhere.

- Baskets Included: Verify baskets present and fit properly. Replacement baskets cost $40-100 each.

- Gas Connections: Check for obvious damage to gas lines, fittings. Photograph model/serial plate showing gas type (NAT vs LP).

- Exterior Condition: Don't let grease scare you, but note structural issues (bent frame, broken welds, damaged control panel housing).

Filtration System Verification (Critical)

- Filtration Tray/Cart Present: If listing mentions filtration, verify all components included. Missing filtration equipment makes "filtered fryer" worthless.

- Slide Test: Filtration tray or cart should slide smoothly into position without forcing or binding. , test system with small water volume. Water mistakes clean easily; oil mistakes cost thousands.

Powered Testing (If Available)

- Ignition: Gas fryers should light quickly with blue flame pattern across entire burner. Yellow flame = incomplete combustion or wrong orifice.

- Temperature Control: Set thermostat to 350°F, allow 15-20 minutes, verify actual temperature with separate thermometer. Drift beyond 10-15°F indicates thermostat issues.

- Safety Shutoff: High-limit safety should prevent overheating. Lift thermocouple to verify pilot cuts off.

- Electrical Components: For electric fryers, verify heating elements activate, no blown fuses, control panel functions properly.

- Unusual Sounds: Excessive rattling, grinding, or vibration during heating indicates mechanical problems.

Pressure Fryer Specific Checks

- Lid Seal: Gasket should be intact without cracking or gaps. Replacement gaskets expensive but necessary for safe operation.

- Pressure Gauge: Verify gauge present and registers pressure during operation.

- Safety Release: Pressure release valve must function properly. This is non-negotiable safety equipment.

- Locking Mechanism: Lid lock should engage positively with audible/tactile confirmation. Loose locks = catastrophic failure potential.

Auction Strategy and Hidden Costs

Setting Your Maximum Bid

Calculate true landed cost before bidding:

💰 Total Cost of Ownership Calculator

Example: 2-Bay Gas Floor Fryer

- Winning Bid: $300

- Buyer's Premium (10-15%): +$45

- Sales Tax (6%): +$21

- Pickup/Delivery: $0-500 depending on location

- Installation: $200-500 (gas connections, positioning)

- Initial Oil Fill (40 lbs): $60

- Cleaning/Prep: $50-200 (degreaser, labor)

- Missing Components: Baskets ($80), filtration parts ($100-400)

True Landed Cost: $756-$1,706 depending on variables

Compare this to retail pricing ($2,500-4,000 for equivalent new unit) and used dealer pricing ($1,200-2,000 for refurbished). The auction advantage exists but requires realistic budgeting beyond hammer price.

Buyer Mistakes to Avoid

- Underestimating Capacity Needs: The #1 buyer error. Fry station getting "in the weeds" slows down entire kitchen. Overestimate volume requirements—adding a second fryer later costs more than buying correctly initially.

- Ignoring Voltage/Gas Type: "Great deal" on 480V 3-phase fryer means nothing if your location has 208V. Verify infrastructure compatibility before bidding.

- Overlooking Oil Costs: 40 lb fryer @ $0.15/lb × weekly changes = $312/year. Factor ongoing consumables into equipment budget.

- Filtration Component Verification: "Includes filtration" in listing requires physical verification. Missing $400 filtration cart eliminates the value proposition.

- Unknown Brand Gamble: Saving $100 buying import brand costs thousands when proprietary component fails with no replacement available. Penny wise, pound foolish.

When to Walk Away

- Vat Structural Damage: Cracks, severe warping, through-rust cannot be economically repaired. Pass.

- Missing Critical Components: Burner assemblies, control panels, drain valves cost hundreds to replace. Factor into bid or skip.

- Pressure Fryer Safety Issues: Damaged locking mechanisms, bad gaskets, or malfunctioning pressure release valves create liability. Unless you're qualified technician, avoid problem pressure fryers.

- Bidding Wars: Set maximum based on landed cost calculations. Don't let auction fever push beyond breakeven vs used dealer pricing.

Final Thoughts: Fryers as Strategic Kitchen Assets

Unlike specialized equipment serving narrow purposes, commercial fryers represent strategic kitchen assets enabling menu diversification, margin improvement, and customer satisfaction. The data from 1,000+ auction sales reveals clear patterns:

- Entry barrier is low: Functional countertop units start at $75 median, making fried menu testing accessible.

- Scale appropriately: Floor gas fryers at $210 median serve most operations. Pressure and ventless systems justify premiums for specific use cases.

- Brand hierarchy matters less: Unlike mixers where motor quality varies dramatically, gas fryers are simple equipment. Mid-tier brands (Pitco, Frymaster, Vulcan) perform nearly identically to premium Henny Penny for standard applications.

- Filtration pays for itself: The 6.9x auction premium ($900 vs $130) recovers through oil savings within 12-18 months while improving food quality.

- Electric is viable: Unlike griddles where electric performance suffers, fryer electric units work fine when gas unavailable. Don't compromise location for gas access.

The auction opportunity exists because many operators underestimate fryer needs initially, then upgrade to larger systems, creating steady secondary market supply. Smart buyers benefit from this upgrade cycle by purchasing quality used equipment at fraction of retail cost.

Start with data, verify with inspection, calculate true landed costs, and bid accordingly. The equipment guides we publish aren't just pricing references—they're operational playbooks from auctioneers who've moved thousands of units and understand what works in real-world kitchens.

Ready to Add Fryer Capacity?

PCI Auctions moves 600-900 lots weekly, including diverse fryer inventory from countertop units to premium multi-bay systems. Register for our next auction to access professional equipment at auction pricing.

View Current Auctions

PCI Auctions East Coast

141 W End Drive, Manheim, PA 17545

Phone: 717-945-3986

Monday-Friday: 8:00 AM - 5:00 PM