The Complete Guide to Commercial Coffee Grinders 2025

The Complete Commercial Coffee Grinder Buyer's Guide 2025

Data-Driven Analysis of 247 Auction Sales | Expert Insights on Mahlkonig, Bunn, Mazzer & More

Why Commercial Coffee Grinders Matter More Than You Think

In specialty coffee operations, the grinder determines beverage quality more than any other equipment piece. A $15,000 espresso machine paired with a mediocre grinder produces mediocre espresso. The inverse—exceptional grinder with adequate espresso machine—delivers excellent results. Consistent particle size distribution, minimal heat generation during grinding, and precise grind adjustment separate craft coffee from gas station coffee.

For high-volume bulk operations like convenience stores, restaurants, and institutional settings, grinding determines per-cup costs and operational efficiency. Pre-ground coffee costs 40-60% more than whole bean equivalents. Commercial grinders delivering 3-10 pounds per minute throughput transform bulk whole bean purchases into cost savings measured in thousands of dollars annually.

The auction market for commercial coffee grinders offers exceptional value across all operational tiers. Our analysis of 247 grinder sales over 12 months reveals pricing patterns, brand performance data, and inspection intelligence unavailable elsewhere. This guide translates auction floor experience into bidding strategy.

Mahlkonig premium flat burr grinder - the craft coffee industry standard commanding $1,310 median auction price

Market Reality: 247 Sales Analyzed

Auction Database Overview

- Total Sales: 247 commercial coffee grinders over 12 months

- Median Price: $195 (typical grinder)

- Mean Price: $361.65 (pulled up by premium espresso grinders)

- Price Range: $0.26 to $2,350

- 25th Percentile: $67 (budget/salvage tier)

- 75th Percentile: $450 (quality working units)

Retail Comparison: Median auction price of $195 represents 60-85% discount from retail equivalents ($600-$3,000+ new). Premium Mahlkonig grinders selling at $1,310 median retail for $3,500-$6,000+ new.

Brand Performance Hierarchy

Brand reputation directly impacts auction pricing. The data reveals clear tier structure based on 247 sales:

| Brand | Units Sold | Market Share | Median Price | Price Range |

|---|---|---|---|---|

| Mahlkonig | 35 | 14% | $1,310 | $33 - $2,350 |

| Anfim | 2 | 1% | $1,161 | $1,122 - $1,200 |

| Nuova Simonelli | 7 | 3% | $625 | $150 - $1,407 |

| Avantco | 3 | 1% | $327 | $326 - $450 |

| Mazzer | 9 | 4% | $275 | $105 - $750 |

| Ditting | 9 | 4% | $222 | $100 - $1,725 |

| Bunn | 70 | 28% | $190.50 | $0.26 - $1,000 |

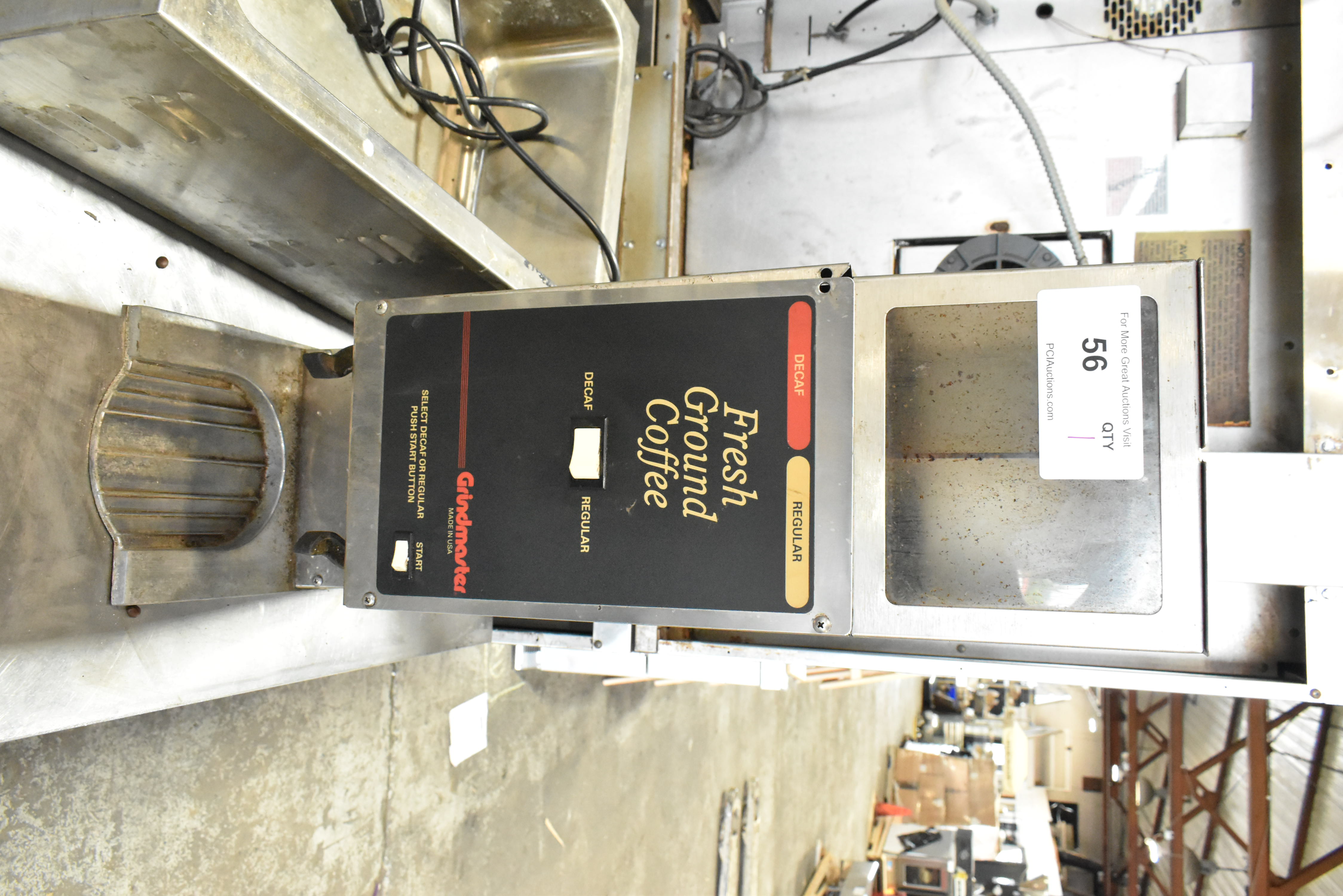

| Grindmaster | 14 | 6% | $123.50 | $20 - $312 |

| Compak | 3 | 1% | $95 | $48 - $180 |

| Other Brands | 92 | 37% | $88 | $3.50 - $900 |

| Rancilio | 2 | 1% | $71.50 | $23 - $120 |

| Casadio | 1 | <1% | $31 | $31 |

Mahlkonig E80 Supreme - premium flat burr grinder commanding top auction prices

The Mahlkonig Premium Explained

Mahlkonig commands 6.7X the median price of Bunn ($1,310 vs $190.50) for legitimate reasons. Each Mahlkonig model fills a specific industry niche with flat burr grinders featuring powerful AC motors, exceptional build quality, and unmatched grind consistency. With proper maintenance, Mahlkonig grinders outperform most competitors while delivering particle size uniformity critical for espresso extraction. The EK43 model specifically has achieved cult status in specialty coffee, making it one of the most sought-after grinders at any price point.

Top 10 Highest Performing Sales

The premium tier reveals buyer willingness to invest in proven equipment:

| Rank | Description | Price | Brand |

|---|---|---|---|

| 1 | Mahlkonig EK43 (2021) | $2,350 | Mahlkonig |

| 2 | Mahlkonig Commercial Grinder | $2,001 | Mahlkonig |

| 3 | Mahlkonig E80 Supreme | $1,825 | Mahlkonig |

| 4 | Ditting KR1403 Commercial | $1,725 | Ditting |

| 5 | Mahlkonig E65 GBW | $1,500 | Mahlkonig |

| 6 | Mahlkonig Grinder | $1,450 | Mahlkonig |

| 7 | Nuova Simonelli Mythos One | $1,407 | Nuova Simonelli |

| 8 | Mahlkonig Grinder | $1,350 | Mahlkonig |

| 9 | Mahlkonig E65 GBW | $1,301 | Mahlkonig |

| 10 | Anfim Super Caimano | $1,200 | Anfim |

Key Observation: Mahlkonig captures 8 of the top 10 sales positions. Ditting and Nuova Simonelli represent the only non-Mahlkonig grinders breaking into the premium tier. This concentration reflects craft coffee industry consensus regarding flat burr grinder supremacy for espresso applications.

Mazzer Super Jolly - solid mid-tier performer at $275 median auction price

Understanding Burr Grinder Technology

Nearly all commercial coffee grinders utilize burr grinding technology. Blade grinders produce inconsistent particle sizes unsuitable for commercial applications. Burr grinders crush beans between two abrasive surfaces, creating uniform particle size essential for proper extraction.

Flat Burr vs Conical Burr Design

The fundamental design choice in commercial grinders creates different performance characteristics:

Flat Burr Grinders

- Design: Two parallel ring-shaped burrs with teeth pointing in opposite directions

- Particle Uniformity: Completely uniform consistency critical for espresso

- Motor Requirements: Larger AC motors needed for consistent torque

- Heat Generation: Higher heat during grinding (minimal impact with proper technique)

- Retention: More grounds retained in grind chamber between uses

- Applications: Espresso, specialty coffee, craft applications prioritizing consistency

- Price Premium: Command higher auction prices (Mahlkonig $1,310 median)

Flat burr grinding surfaces - precision-engineered for espresso consistency (replacement burrs available at auction)

Conical Burr Grinders

- Design: Cone-shaped inner burr nested inside ring-shaped outer burr

- Particle Uniformity: Very consistent but not perfectly uniform

- Motor Requirements: Smaller motors sufficient (gravity assists)

- Heat Generation: Lower heat production

- Retention: Less ground retention due to gravity assist

- Speed: Faster grinding throughput

- Noise: Quieter operation than flat burrs

- Applications: Bulk operations, drip coffee, general commercial use

- Efficiency: Lower operating costs (smaller motor, faster cycles)

Bunn G3 HD bulk grinder with prominent grind adjustment wheel - conical burr design for high-volume operations

Inspection Reality: Determining flat vs conical burr configuration requires either removing the bean hopper (when possible) to view burrs directly, or researching the specific model number. Spec plates typically do not identify burr type. For auction preview, note the model number and research specifications before bidding. Flat burr grinders generally feature larger, more substantial motor housings and command premium pricing.

Application-Specific Considerations

The flat vs conical debate resolves through intended application:

| Operation Type | Recommended Burr Type | Reasoning |

|---|---|---|

| Craft coffee shops (espresso) | Flat | Particle uniformity critical for extraction consistency |

| High-volume cafes | Both | Flat for espresso bar, conical for bulk drip coffee |

| Convenience stores | Conical | Speed and efficiency over micro-consistency |

| Restaurants (drip service) | Conical | Lower cost, adequate consistency for drip applications |

| Institutional (hospitals, schools) | Conical | Volume capacity and operational efficiency |

| Specialty roasters | Flat | Sample roasting and quality control requires precision |

Professional Operations: Serious coffee operations frequently deploy both burr types. Flat burr grinders (Mahlkonig, Mazzer) handle espresso applications where consistency determines beverage quality. Conical burr grinders (Bunn, Grindmaster) provide bulk grinding for drip coffee, french press, and general service where speed and efficiency matter more than microscopic particle uniformity.

Bunn commercial grinder - volume leader capturing 28% of auction sales at $190.50 median

Grinder Types and Operational Categories

Commercial grinders segment into distinct operational categories based on automation level and dispensing method:

Automatic Grinders

Fully automated grinding with preset controls. Operator selects grind setting and quantity, grinder handles execution. Common in high-volume convenience stores and institutional settings. Bunn and Grindmaster dominate this category. These units often feature multiple bean hoppers for regular/decaf or multiple roast profiles.

Grindmaster 2-hopper automatic grinder - ideal for high-volume operations requiring multiple bean varieties

Semi-Automatic Grinders

Manual activation with automatic metering. Operator initiates grind cycle, grinder dispenses preset amount. Popular in coffee shops balancing speed with control. Most espresso grinders operate semi-automatically, grinding directly into portafilters on demand.

Portion-Controlled Grinders

Dispense exact preset amounts directly into brew baskets or filters. Standardizes coffee-to-water ratios eliminating operator variation. Critical for franchises and multi-unit operations requiring consistency across locations. Often integrated with automatic brewing systems.

Brand new scratch & dent Bunn portion control grinder - precision dispensing for standardized brewing

Visual Identification During Preview

Control panel design reveals operational category:

- Automatic: Digital displays, multiple preset buttons, timer controls visible

- Semi-Automatic: Simple on/off switch or momentary contact button, minimal controls

- Portion Control: Portion size selectors, integrated with brew basket holders

Specification plates provide definitive classification. During preview, photograph spec plates for research before bidding.

Doser vs Doserless Configuration

Espresso grinders further divide into doser and doserless designs:

Doser Grinders

Feature grinding chamber collecting ground coffee. Operator pulls lever dispensing preset portion into portafilter. Advantages include speed in high-volume operations and cleaner workflow (grounds contained until dispensing). Suitable for busy coffee shops where grind demand creates steady throughput preventing grounds from sitting in doser chamber.

Mazzer Super Jolly with doser - lever-operated dosing chamber for high-volume espresso service

Doserless (On-Demand) Grinders

Grind directly into portafilter when activated. Maximum freshness—beans remain whole until moments before brewing. Reduces waste (no grounds sitting in doser). Preferred for lower-volume operations and specialty cafes prioritizing freshness over speed. Mahlkonig grinders predominantly feature doserless design.

Mahlkonig doserless grinder - on-demand grinding for maximum freshness in craft coffee applications

Doser vs Doserless Decision Framework

Choose doser if: High volume operations (50+ espresso drinks hourly), speed prioritized, consistent demand prevents grounds from sitting.

Choose doserless if: Craft coffee operation, lower volume (under 30 drinks hourly), freshness premium justifies slightly slower workflow.

Auction Impact: Doser vs doserless does not significantly affect auction pricing in our 247-unit database. Brand reputation and condition drive pricing more than dosing method. Both configurations command similar prices within brand categories.

Multi-Hopper Systems

Higher-end bulk grinders feature multiple bean hoppers enabling operators to offer variety without equipment duplication:

- Regular and decaf coffee options

- Multiple roast profiles (light, medium, dark)

- Flavored and non-flavored varieties

- Single-origin selection

Bunn 2-hopper grinder - dual bean variety capability without equipment duplication

Multi-hopper units typically feature selector switches or buttons allowing operators to choose which hopper feeds the burr mechanism. These systems particularly valuable for operations requiring variety without dedicating counter space and budget to multiple grinders. Auction pricing for multi-hopper units runs 10-25% premium over single-hopper equivalents in same condition.

Critical Inspection Points

Unlike some commercial equipment categories, coffee grinders reveal operational history through visual inspection. Understanding what to examine during preview separates successful bidders from disappointed ones.

Bean Hopper Condition and Interlocking Systems

Bean hoppers present the most common "does not power on" failure point. Many grinders feature mechanical or magnetic interlocking preventing burr activation when hopper is improperly seated or removed. This safety feature protects operators from exposed burrs but creates troubleshooting challenges.

Hopper interlock mechanism - magnetic and manual safety features preventing operation without proper hopper seating

Testing Limitation: Grinders tagged "tested and does not power on" frequently function perfectly once hopper interlocks are properly aligned. During auction preview, testing teams check for power but may not have model-specific hopper seating knowledge. Many "non-working" grinders only require correct hopper installation. This creates opportunity—bidders with model knowledge can acquire functional grinders at "parts machine" pricing.

Hopper Inspection Checklist:

- Check for cracks in hopper body (plastic hoppers crack from overtightening)

- Examine interlock tabs/magnets for damage or missing components

- Verify hopper lid presence (some models require lid for operation)

- Note hopper capacity (affects operational suitability for buyer's application)

- Photograph hopper model/part numbers visible on unit

4.4-pound capacity hopper - typical size for commercial espresso grinder applications

Hopper Replacement Economics

Replacement hoppers vary dramatically in cost based on brand and complexity:

| Brand Category | Replacement Cost | Availability |

|---|---|---|

| Bunn / Grindmaster | $20-$60 | Excellent - widely stocked |

| Mazzer / Compak | $80-$150 | Good - specialty suppliers |

| Mahlkonig / Ditting | $150-$250 | Good - authorized dealers |

| Nuova Simonelli | $100-$180 | Good - espresso suppliers |

| Unknown brands | $40-$200 | Poor - model-specific challenges |

Hopper replacement costs matter because specific size, shape, capacity, and interlock configuration must match grinder model. Generic hoppers rarely work. Budget potential hopper replacement when bidding on grinders with damaged or missing hoppers, particularly premium brands where replacement costs approach $250.

Mechanical interlock detail - hopper neck must lock into position to complete circuit and enable grinder operation

Burr Condition Assessment

Burr wear determines grinder lifespan and grind quality. Worn burrs produce inconsistent particle sizes degrading beverage quality. Unfortunately, burr inspection presents challenges:

Visual Inspection Limitations: Burr wear operates at microscopic scale. Fractional millimeter variances in burr tooth height create performance degradation. Visual inspection without precise measurement tools provides limited information. Even removing hoppers for burr access (when possible) only reveals obvious damage—chips, cracks, major corrosion.

Reliable Indicators: Overall grinder condition provides better prediction than attempting burr wear assessment. Well-maintained grinders with clean exteriors, organized cable management, and general care typically feature better-maintained burrs. Neglected units showing built-up grounds, corrosion, and poor general condition likely feature worn burrs.

What You CAN Inspect

- Grinding chamber cleanliness: Remove hopper if possible, examine for caked grounds and residue buildup

- Visible burr damage: Obvious chips, cracks, or major corrosion (rare but catastrophic)

- Ground coffee accumulation: Excessive buildup indicates poor maintenance across entire unit

- Exit chute condition: Should be relatively clean; heavy staining and caking suggest neglect

- Adjustment mechanism: Should move smoothly without binding or excessive play

Heavy staining and residue buildup - warning signs of deferred maintenance likely including worn burrs

Burr Replacement Economics

Burr replacement costs factor into bidding strategy for heavily-used units:

| Grinder Category | Burr Set Cost | Labor (if outsourced) |

|---|---|---|

| Bunn bulk grinders | $40-$100 | $80-$150 |

| Grindmaster commercial | $50-$120 | $80-$150 |

| Mazzer espresso | $100-$200 | $100-$200 |

| Mahlkonig premium | $200-$400 | $150-$250 |

| Ditting Swiss | $180-$350 | $150-$250 |

DIY burr replacement varies by model. Bunn and Grindmaster units feature relatively straightforward replacement (basic tools, 30-60 minutes). Premium espresso grinders require more complex disassembly and burr calibration. Unless experienced with specific model, professional service recommended for espresso grinders to ensure proper burr alignment affecting grind quality.

Specification Plate Documentation

Every commercial grinder features specification plate providing critical information:

- Exact model number (essential for parts research)

- Voltage and phase requirements

- Amperage draw

- Manufacturing date (on some models)

- Serial number

- Safety certifications (UL, NSF, CE)

Specification plate - photograph during preview for model research and parts availability verification

Preview Strategy: Photograph specification plates on all grinders under consideration. Research model numbers before bidding to verify:

- Burr type (flat or conical)

- Typical retail pricing (establishes value baseline)

- Parts availability (critical for "does not power on" units)

- Known issues or failure points for specific models

- Replacement burr costs

Overall Condition Indicators

General maintenance quality predicts functional condition better than attempting technical assessment:

Positive Indicators:

- Clean exterior showing regular wiping/maintenance

- Organized power cord and cable management

- Minimal ground coffee buildup in accessible areas

- Smooth adjustment mechanism operation

- Intact safety guards and protective covers

- Clear labeling/settings still legible

Warning Signs:

- Heavy ground coffee accumulation throughout unit

- Corrosion or rust on metal components

- Damaged or missing adjustment controls

- Cracked or damaged housing/chassis

- Evidence of liquid damage (water, coffee, cleaning solutions)

- Missing safety components or guards

Coffee Residue vs Neglect: Some coffee staining is normal and expected. Heavy caking, however, indicates operational neglect. Coffee oils become rancid over time, and units showing heavy caked residue likely suffered from deferred maintenance including missed burr cleaning, adjustment calibration, and preventive service.

The Brand New Scratch & Dent Opportunity

Brand new scratch and dent (BNSD) grinders represent exceptional auction value. These units arrive from major wholesalers with cosmetic imperfections—dents, scratches, packaging damage—preventing retail sale despite full functionality.

BNSD Grinder Value Proposition

- Condition: New burrs never used, zero operational hours

- Functionality: Fully tested and working (critical designation)

- Warranty Status: Typically eligible for manufacturer warranty

- Cosmetic Damage: Dings, scratches, dents—purely aesthetic

- Auction Pricing: 40-70% below retail equivalents

BNSD Bunn portion control grinder - cosmetic imperfection, full functionality, substantial savings

Why BNSD Units Excel: Most commercial coffee grinders operate in back-of-house locations where customers never see them. A dent on a bulk grinder or scratch on espresso grinder housing affects nothing operationally. For gas stations, convenience stores, restaurant back areas, and institutional kitchens, cosmetic condition is irrelevant. BNSD units deliver new-unit performance and reliability at used-unit pricing.

BNSD Pricing Reality

Our database includes numerous BNSD units across price tiers:

| Unit Description | Auction Price | Retail Equivalent | Savings |

|---|---|---|---|

| BNSD Mahlkonig Premium | $2,399 | $5,500-$6,000 | 57-60% |

| BNSD Avantco BCG3 Bulk | $327 | $800-$900 | 59-64% |

| BNSD Bunn Portion Control | $240-$350 | $700-$1,000 | 65-76% |

| BNSD Estella Espresso | $400 | $900-$1,200 | 55-67% |

BNSD Mahlkonig premium grinder sold for $2,399 (retail $5,500-$6,000) - 60% savings on industry-leading equipment

Bidding Strategy for BNSD Units: Competition intensifies on BNSD grinders because buyers recognize value proposition. These units frequently attract multiple serious bidders willing to approach or exceed 50% of retail pricing. Strategy depends on application:

For critical operations (coffee shops, specialty cafes) where equipment failure stops revenue, BNSD units justify aggressive bidding. Paying 60% of retail for new-condition equipment with warranty eligibility still delivers substantial savings while minimizing operational risk.

For general commercial use (restaurants, convenience stores, institutional), BNSD premium may not justify aggressive bidding if well-maintained used units available at 30-40% of retail pricing.

Maximum BNSD Bid Calculation

Determine maximum BNSD bid using retail comparison:

- Research current retail pricing for identical new model

- Calculate 70% of retail price as absolute ceiling

- Set comfortable maximum at 50-60% of retail

- If bidding exceeds comfortable maximum, evaluate used alternatives

Example: Mahlkonig grinder retailing $5,500 new. Absolute ceiling: $3,850 (70%). Comfortable maximum: $2,750-$3,300 (50-60%). If auction bidding pushes toward $3,500+, consider used Mahlkonig units in excellent condition at $1,300-$2,000 providing better value despite operational hours.

Technical Requirements and Setup

Electrical Requirements

Commercial coffee grinders predominantly operate on standard 120V single-phase power. Unlike many commercial kitchen equipment categories requiring 208-240V service, most grinders plug into standard outlets.

Standard Configurations:

- 120V, 1-phase: 95% of grinders in our database (bulk and espresso)

- 220-240V, 1-phase: Some European-spec imports

- 208-240V, 3-phase: Very rare, only some large commercial units

Amperage draw varies by motor size. Bulk grinders with larger motors typically draw 10-15 amps. Espresso grinders with smaller motors operate at 5-10 amps. Standard 15-amp or 20-amp circuits handle most commercial grinders without dedicated electrical service.

Installation Advantage: Unlike commercial ovens, refrigeration, or dishwashers requiring electrical contractor service, most coffee grinders simply plug into existing outlets. This dramatically reduces installation costs and deployment timeline.

Initial Setup and Seasoning

New or newly-acquired grinders require seasoning before regular service. This process removes manufacturing residue, beds in burrs to optimal performance, and allows adjustment calibration.

Seasoning Process:

- Start with coarse setting: Set grinder to coarsest grind adjustment

- Use inexpensive dark roast: Dark (oily) beans provide better cleaning action than light roasts. Purchase cheap whole bean coffee specifically for seasoning—3-10 pounds depending on grinder size

- Initial grind: Process 2-3 pounds through grinder at coarse setting, discarding grounds

- Gradual adjustment: Slowly adjust to finer settings over next several pounds

- Final calibration: Once reaching desired grind setting for operational use, grind final 1-2 pounds to verify consistency

- Total volume: Budget 3-5 pounds for small espresso grinders, 5-10 pounds for bulk commercial units

Why Seasoning Matters: Burrs perform optimally after initial use removes microscopic manufacturing residue and edges achieve final geometry through initial grinding friction. Attempting to achieve final grind consistency without seasoning results in suboptimal particle distribution. The 3-10 pound seasoning investment (typically $20-$40 in cheap coffee) ensures optimal performance from first operational day.

Grind Adjustment and Calibration

All commercial burr grinders feature grind adjustment mechanisms. Complexity varies by model, but fundamental concept remains consistent—adjusting burr spacing changes particle size.

Adjustment Types:

- Stepped adjustment: Discrete positions (coarse, medium, fine) with mechanical detents

- Stepless adjustment: Continuous adjustment across full range without preset positions

- Micro-adjustment: Fine-tuning within main adjustment range (common on espresso grinders)

Prominent grind adjustment wheel on Bunn bulk grinder - simple, accessible grind size control

Operational Reality: Despite marketing emphasis on infinite adjustment capability, most commercial operations set grind once and rarely adjust. Coffee shops may adjust for seasonal bean changes or new roast profiles, but daily adjustment is exception rather than rule. Constant adjustment accelerates mechanism wear and introduces consistency variability. Settle on appropriate grind setting for application and bean type, then maintain that setting absent specific reason for change.

Ongoing Maintenance Requirements

Coffee grinders demand less maintenance than most commercial equipment but benefit from regular attention:

Daily Tasks:

- Wipe exterior surfaces removing coffee dust and oils

- Empty any doser chambers before closing

- Verify hopper bean level and refill as needed

- Quick visual inspection for obvious issues

Weekly Tasks:

- Vacuum or brush grounds from accessible areas

- Wipe down hopper interior if possible

- Check adjustment mechanism for excessive play or binding

- Inspect exit chute for excessive buildup

Monthly Tasks:

- Remove and clean hopper thoroughly

- Deep clean accessible grinding chamber areas

- Inspect power cord and connections

- Verify grind consistency meets standards

Annual/Preventive Service:

- Professional burr inspection and measurement

- Burr replacement if wear exceeds specifications

- Motor and bearing lubrication (model-dependent)

- Full disassembly and deep cleaning

- Adjustment mechanism calibration

- Electrical connection inspection

Professional annual service costs $100-$300 for bulk grinders, $150-$400 for espresso grinders. This preventive maintenance extends equipment life and maintains grind quality. Operations running grinders 8+ hours daily should budget for annual service. Lower-volume operations may extend service intervals to 18-24 months.

Bidding Strategy by Price Tier

The 247-unit database reveals distinct price tiers with different risk/reward profiles. Successful bidding requires understanding these tiers and matching strategy to operational needs and risk tolerance.

Tier 1: Under $100 (25% of Sales)

Median: $67 | Typical condition: Parts machines, salvage, "does not power on"

This tier splits between true parts machines and hidden gems. Units tagged "does not power on" include both legitimately failed grinders and units with simple hopper interlock issues. Strategy depends on technical capability and parts needs.

Good candidates:

- Recognized brands (Bunn, Mazzer, Grindmaster) with intact burrs and hoppers

- Units showing "does not power on" with no obvious damage

- Grinders needed specifically for parts inventory

- Backup units for operations with existing same-model grinders

Avoid:

- Unknown brands with no parts availability research

- Units with obvious motor damage or burning smell

- Grinders missing critical components (burrs, hoppers, adjustment mechanisms)

- Heavy corrosion or liquid damage evidence

Mahlkonig "does not power on" sold for $900 - brand reputation and salvageable components justify premium even without confirmed functionality

Expected outcome: 40-60% success rate achieving functional status. Budget $100-$300 additional investment for parts/service. Even with repairs, total investment ($100 purchase + $200 repairs = $300 total) delivers exceptional value for grinders retailing $800-$2,000+.

Tier 2: $100-$300 (35% of Sales)

Median: $190 | Typical condition: Working bulk grinders, lower-volume espresso units

This represents highest-volume tier capturing Bunn bulk grinders, Grindmaster commercial units, and entry-level espresso grinders. Risk/reward ratio favors buyers at this level—most units function adequately with minor service needs.

What $100-$300 buys:

- Bunn G-series bulk grinders in working condition

- Grindmaster commercial units tested and functioning

- Entry Mazzer or Compak espresso grinders needing minor service

- Multi-hopper systems from volume brands

- Well-used but functional mid-tier units

Typical $190 tier unit - working Bunn bulk grinder delivering reliable performance for general commercial applications

Bidding approach:

- Prioritize "tested and working" designation over condition concerns

- Accept some cosmetic wear—focus on mechanical function

- Verify brand and model enable parts sourcing if needed

- Budget $50-$150 for cleaning and minor service post-purchase

- Set maximum bid at $300-$350 to avoid approaching retail pricing

Best use cases: General commercial operations prioritizing functionality over perfection. Restaurant coffee service, convenience store bulk grinding, institutional food service, catering operations, and anywhere coffee grinding represents utility function rather than revenue generation.

Tier 3: $300-$600 (20% of Sales)

Median: $450 | Typical condition: Quality espresso grinders, premium bulk units, better-maintained equipment

This tier delivers substantially better equipment quality. Mazzer espresso grinders, higher-end Bunn models, and well-maintained mid-tier units populate this range. Functionality probability exceeds 85% with typical service needs limited to burr replacement or minor adjustments.

What $300-$600 buys:

- Mazzer Super Jolly and similar espresso grinders

- Ditting commercial units in good condition

- Newer Bunn models with low operational hours

- Nuova Simonelli entry models

- Well-maintained multi-hopper systems

Mazzer Super Jolly at $275—quality espresso grinding for shops prioritizing consistency without Mahlkonig premium

Target buyers: Coffee shops opening or expanding, restaurants adding espresso service, mobile coffee operations, and any business where coffee quality impacts customer perception. Equipment at this tier supports revenue-generating applications justifying the investment premium.

Bidding approach:

- Research specific models before auction—know retail equivalents

- Maximum bid should not exceed 50% of retail pricing

- Prioritize units with known parts availability

- Factor burr replacement costs into bid strategy if unit shows heavy use

- Consider condition premium—excellent condition worth 20-30% higher bid

Tier 4: $600-$1,000 (12% of Sales)

Median: $800 | Typical condition: Premium espresso grinders, low-hours units, specialty equipment

This tier delivers near-certainty of functionality combined with equipment quality supporting serious coffee operations. Nuova Simonelli, higher-end Mazzer models, entry Mahlkonig units, and premium Ditting grinders populate this range.

What $600-$1,000 buys:

- Nuova Simonelli Mythos and MDX series

- Mazzer Super Jolly Electronic/Timer models

- Entry Mahlkonig models (K30, E65)

- Ditting KR series in excellent condition

- Like-new condition mid-tier brands

Risk profile: Minimal—units at this price point rarely disappoint. Functionality exceeds 95% with most service needs limited to routine maintenance and cleaning. Investment justifies itself for operations where grind quality directly impacts revenue and reputation.

Best use cases: Established coffee shops, specialty cafes, mobile espresso operations, catering with espresso service, and any business positioning coffee as premium offering rather than commodity.

Tier 5: $1,000-$1,500 (5% of Sales)

Typical condition: Mahlkonig territory, premium brands, excellent condition

Mahlkonig dominates this tier. Units include E65, K30, and other professional models trusted by specialty coffee operations globally. At $1,000-$1,500 auction pricing, these grinders still deliver 50-70% savings from retail equivalents.

Mahlkonig E80 Supreme—premium flat burr grinder representing craft coffee industry standard

Target buyers: Serious specialty coffee operations, espresso-focused cafes, competition-level baristas, coffee roasters, and operations where grind quality represents non-negotiable requirement. At this tier, buyers prioritize capability over price savings.

Tier 6: $1,500+ (3% of Sales)

Top tier: $1,500-$2,350 | Condition: Mahlkonig EK43, premium models, BNSD units

The absolute premium tier. Mahlkonig EK43 units, E80 Supreme models, and brand new scratch and dent premium grinders command these prices. Even at $2,000-$2,350, these units represent 50-65% discounts from $4,000-$6,000 retail pricing.

Bidding at premium tier:

- Research identical model retail pricing before auction

- Set maximum at 70% of retail as absolute ceiling

- Prioritize BNSD units offering warranty eligibility

- Verify seller reputation—premium purchases require confidence

- Consider financing if auction exceeds cash availability

$2,399 Mahlkonig BNSD unit—top tier auction pricing still delivering 55-60% savings from retail equivalent

Who should bid at premium tier: Established specialty coffee operations with proven revenue justifying investment. Coffee shops where equipment quality differentiates brand and supports premium pricing. Roasters requiring sample grinding capability. Competition baristas and coffee professionals. Operations where equipment failure creates substantial revenue loss justifying new-equivalent reliability.

Universal Bidding Principles

- Know retail pricing: Research before bidding—never bid blind

- Factor total cost: Include transportation, service, parts in bidding decision

- Set maximum before auction: Emotional bidding destroys value proposition

- Consider application: Match grinder tier to operational requirements

- Verify parts availability: Unknown brands without parts access rarely justify risk

- Prioritize tested units: "Tested and working" worth 30-50% premium

- Accept cosmetic wear: Function trumps appearance in commercial equipment

- Research brand reputation: Premium brands justify higher bids than generic equivalents

Parts Availability and Service Networks

Long-term ownership success depends substantially on parts availability and service network quality. Unlike purchasing new equipment with warranty support, auction acquisitions require self-sufficient parts sourcing and service relationships.

Brand Service Network Rankings

Based on parts availability, distributor networks, and service technician familiarity:

Tier 1: Excellent Availability

Bunn: Most extensive parts network in United States. Major food service equipment distributors (Parts Town, WebstaurantStore, national suppliers) stock Bunn components for immediate shipping. Local technicians universally familiar with Bunn equipment. Parts typically arrive within 1-3 business days. Replacement burrs, hoppers, motors, control boards widely available. Service documentation comprehensive and accessible.

Grindmaster: Similar to Bunn—large established US brand with broad distributor network. Parts readily available through general food service channels. Technician familiarity high across commercial kitchen service industry. As Middleby Corporation subsidiary, benefits from large company parts logistics and distribution.

Tier 2: Good Availability (Specialty Channels)

Mazzer: Very popular international brand in commercial espresso. Parts widely available through specialist coffee equipment suppliers (Espresso Parts, Prima Coffee, Chris' Coffee Service, Seattle Coffee Gear). Due to popularity, finding parts rarely presents challenges. Multiple US importers and distributors maintain inventory. Service technicians in major metro areas familiar with Mazzer models. Parts typically arrive within 3-7 business days.

Mahlkonig & Ditting: Premium brands (both Hemro Group) representing industry standards for bulk and high-end espresso grinding. Parts well-stocked by specialist coffee equipment importers and major distributors. Strong support networks within specialty coffee community. Parts access adequate but more limited than Bunn or Grindmaster in general food service channels. Technicians in specialty coffee markets (major cities, coffee-focused regions) highly familiar with these brands. Parts typically ship within 5-10 business days, longer for unusual components.

Tier 3: Adequate Availability (Authorized Channels)

Nuova Simonelli: Strong presence in espresso machine market extends to grinder line. Parts available through authorized dealers and specialty suppliers. Network slightly less pervasive than Mazzer or Mahlkonig in US market. Mythos series parts well-supported due to model popularity. Less common models may require longer lead times. Budget 7-14 days for parts acquisition outside major metro areas.

Compak, Anfim, Rancilio: Legitimate commercial brands with US distribution but smaller market presence. Parts available through specialty importers and authorized service centers. May require specific dealer relationships. Lead times vary 7-21 days depending on component and dealer inventory. Best purchased if existing service relationship exists or in markets with strong specialty coffee infrastructure.

Tier 4: Limited/Unknown

Generic imports, house brands, discontinued lines: Parts availability ranges from difficult to impossible. Success depends on component specificity—standard bearings, switches, power cords potentially sourceable through electrical/mechanical suppliers. Proprietary components (burrs, hoppers, control boards specific to model) may be unavailable. Only purchase if:

- Purchasing multiple identical units for parts consolidation

- Unit is BNSD with warranty supporting parts access

- Comprehensive online research confirms parts availability before bidding

- Price so low that parts sourcing challenges acceptable given minimal investment

Common Replacement Parts and Costs

| Component | Bunn/Grindmaster | Mazzer/Compak | Mahlkonig/Ditting |

|---|---|---|---|

| Bean Hopper | $20-$60 | $80-$150 | $150-$250 |

| Burr Set | $40-$100 | $100-$200 | $200-$400 |

| Motor Assembly | $80-$180 | $150-$300 | $250-$500 |

| Control Board | $60-$150 | $100-$250 | $150-$400 |

| Adjustment Ring | $30-$80 | $60-$120 | $80-$180 |

| Power Cord | $15-$30 | $20-$40 | $25-$50 |

| Doser Assembly | N/A | $100-$200 | $150-$300 |

Labor Costs: Professional service rates range $80-$150 per hour. Simple repairs (hopper replacement, adjustment calibration) require 0.5-1 hour. Complex repairs (motor replacement, burr replacement with calibration) require 1-3 hours. Factor service costs into total ownership calculations when evaluating auction purchases.

Ditting commercial grinder—Swiss precision engineering with solid parts availability through specialty channels

Brand-Specific Insights

Mahlkonig: The Craft Coffee Standard

Mahlkonig represents the premium tier for legitimate reasons beyond marketing. Each model fills specific industry niche with flat burr grinders featuring powerful AC motors, exceptional build quality, and unmatched consistency. With proper maintenance, Mahlkonig grinders operate reliably for 10-15+ years in commercial environments.

Notable models in database:

- EK43: Cult status in specialty coffee. Single-dose grinding, exceptional uniformity, suitable for espresso and brew methods. Retail $3,800-$5,500, auction median $2,000-$2,350

- E80 Supreme: High-volume espresso grinding for busy cafes. On-demand dosing, programmable portions. Retail $5,500-$6,500, auction range $1,500-$2,000

- E65 GBW: Mid-tier professional espresso. Grind-by-weight technology for precision. Retail $3,200-$4,000, auction range $1,200-$1,500

- K30: Compact professional espresso grinder. Shop-grade performance in smaller footprint. Retail $2,200-$2,800, auction range $800-$1,200

Why Mahlkonig commands premium: Flat burr uniformity, motor reliability, parts availability, service network quality, brand reputation in specialty coffee, resale value retention. Mahlkonig grinders purchased at auction maintain value—if operation changes direction, Mahlkonig units resell easily.

Bunn: The Volume Workhorse

Bunn captures 28% of auction sales (70 units in database) for good reason. These grinders deliver consistent performance in bulk grinding applications without premium pricing. For restaurants, convenience stores, institutional food service, and anywhere grinding represents utility function rather than craft, Bunn provides exceptional value.

Common models:

- G-series (G1, G2, G3, G9): Bulk grinders for commercial brewing. Simple, reliable, easy to service. Auction range $100-$400

- MHG: Multi-hopper grinder for offering variety. Two or three hopper configurations. Auction range $150-$500

- Portion control models: Automatic dispensing for standardized brewing. Integrates with Bunn brewer systems. Auction range $200-$600

Bunn advantages: Parts everywhere, technicians familiar, simple to service, reliable performance, excellent value. Disadvantages: Not suitable for espresso applications, basic aesthetics, limited craft coffee credibility.

Bunn G3 HD—practical bulk grinding delivering reliable performance at $190 median auction price

Mazzer: The Mid-Tier Performer

Mazzer delivers espresso-grade grinding without Mahlkonig premium. Super Jolly models particularly popular—proven design, solid construction, adequate performance for most coffee shop applications. Not cutting-edge technology, but reliable workhorses at reasonable pricing.

Models in database:

- Super Jolly (Manual/Timer/Electronic): Doser espresso grinder. Various automation levels. Auction range $150-$750, median $275

- Major: Higher-volume espresso grinding. Larger burrs, more powerful motor. Auction range $300-$900

Mazzer position: Better than entry brands (Rancilio, Compak), not premium tier (Mahlkonig, high-end Ditting). Suitable for coffee shops prioritizing reliability over latest technology. Parts readily available, service straightforward, performance adequate for most espresso applications.

Ditting: Swiss Precision

Ditting represents Swiss manufacturing precision. Known for exceptional build quality and longevity. KR series particularly robust—commercial-grade construction supporting decades of reliable operation. Less common in US market than Mahlkonig or Mazzer but well-regarded when available.

Auction range in database: $100-$1,725, median $222. Wide range reflects condition variation—well-maintained Ditting units command premium, neglected units sell as commodity. Notable that even damaged Ditting unit selling for $100 attracted bidders based on brand reputation and salvageable components.

Ditting KR series—Swiss engineering delivering exceptional build quality and multi-decade operational life

Nuova Simonelli: Espresso Specialist

Primarily known for espresso machines, Nuova Simonelli grinder line focuses on espresso applications. Mythos series particularly popular—temperature control, micrometrical adjustment, quality construction. Less common than Mazzer but solid performers when available.

Database shows 7 units ranging $150-$1,407, median $625. Premium units (Mythos One at $1,407) approach Mahlkonig pricing territory. Mid-range units provide solid value for espresso-focused operations.

Lesser-Known Brands: The Deal Opportunity

The "Other" category (92 units, 37% of sales) includes numerous manufacturers making functional commercial grinders. Brands like Curtis, Fetco, Carimali, Conti, and various European manufacturers produce quality equipment overshadowed by major names. This creates opportunity:

- Conti Italian grinder: Sold $200 auction (example from database). Comparable Mazzer might sell $400-$600. If functional and parts available, represents exceptional value

- Curtis bulk grinders: BNSD units selling $240. Solid commercial grade, adequate parts availability, half the price of Bunn equivalent

- Fetco commercial units: Well-regarded in commercial coffee circles. Less name recognition than Bunn but comparable quality

Conti Italian grinder sold $200—lesser-known brands create exceptional value opportunities for informed buyers

Lesser-known brand strategy: Research before bidding. Verify parts availability through online searches and supplier contacts. If parts accessible and unit tests functional, these grinders deliver best value-per-dollar in auction market. Risk increases with unknown brands, but potential rewards justify research investment.

Nuova Simonelli grinder—espresso specialist brand offering quality alternative to Mazzer/Mahlkonig

Post-Purchase: First Steps and Testing

Auction acquisition represents beginning rather than conclusion of equipment procurement process. Proper post-purchase procedures maximize long-term success.

Transportation and Handling

Coffee grinders feature precision components requiring careful handling:

- Remove and pack hoppers separately: Prevents damage to hopper or interlock mechanisms during transport

- Secure or remove doser assemblies: If equipped, doser chambers vulnerable to impact damage

- Pad motor housing: Protect external surfaces from shipping damage

- Keep upright: Transport in normal operating position when possible

- Avoid excessive vibration: Secure properly in vehicle to minimize vibration affecting burr alignment

Initial Inspection and Cleaning

Before operational testing, complete thorough cleaning:

- Exterior cleaning: Remove accumulated coffee dust, oils, and residue from all external surfaces

- Hopper cleaning: Wash hopper thoroughly with warm soapy water, rinse completely, dry before reinstalling

- Grinding chamber access: If possible without disassembly, vacuum and brush accessible grinding chamber areas

- Exit chute cleaning: Clear any accumulated grounds from dispensing chute

- Burr inspection: If accessible, examine burrs for obvious damage or excessive wear

Functionality Testing

Systematic testing reveals operational status and service needs:

- Power test (no beans): With hopper removed and empty, power unit briefly. Motor should spin smoothly without grinding, unusual noises, or burning smells. Immediately power off after verifying motor function.

- Hopper interlock test: Install hopper per manufacturer design. Verify unit powers on with hopper properly seated. Test that removing hopper immediately stops grinder (safety interlock function).

- Adjustment test: Cycle through grind adjustment range. Mechanism should move smoothly without binding or excessive play. Do not force—if adjustment binds, investigate before proceeding.

- Seasoning grind (2-3 pounds): Load cheap dark roast beans, set to coarse grind, process 2-3 pounds. Monitor for unusual noises, excessive heat, or mechanical issues. This initial seasoning removes manufacturing/storage residue.

- Grind quality test: After seasoning, grind small batch at intended operational setting. Examine grounds for uniformity. Widely varying particle sizes indicate burr wear or calibration needs.

- Extended run test: Process additional 2-3 pounds monitoring temperature. Motor housing should warm but not become uncomfortably hot to touch. Excessive heat indicates bearing wear or motor issues.

Common Issues and Solutions

| Issue | Likely Cause | Solution |

|---|---|---|

| Won't power on | Hopper interlock not seated | Research proper hopper installation for model |

| Motor runs but won't grind | Burrs jammed with debris | Disassemble and clean grinding chamber |

| Inconsistent grind | Worn burrs or poor calibration | Professional burr inspection/replacement |

| Excessive noise | Bearing wear or foreign object | Professional service required |

| Won't dispense (doser) | Doser mechanism jammed | Disassemble and clean doser assembly |

| Motor overheating | Bearing wear or excessive load | Reduce grinding load, service bearings |

| Adjustment won't hold | Worn adjustment mechanism | Parts replacement required |

When to Seek Professional Service

Some issues require professional attention:

- Motor problems: Unusual noises, smoking, failure to run, excessive heat

- Electrical issues: Intermittent operation, power fluctuations, control failures

- Burr replacement: Unless experienced with specific model, professional installation ensures proper alignment

- Calibration needs: Grind quality issues beyond simple adjustment correction

- Structural damage: Cracked housings, damaged mounting points, alignment issues

Professional diagnostic service costs $80-$150 typically. This investment prevents incorrect repairs and identifies actual service needs versus assumed problems. For premium grinders (Mahlkonig, high-end Mazzer, Ditting), professional service strongly recommended over DIY experimentation.

Final Assessment

Commercial coffee grinders represent essential infrastructure across coffee service spectrum—from convenience store bulk grinding to craft coffee espresso precision. The auction market delivers exceptional value at all operational tiers.

Our analysis of 247 grinder sales reveals consistent patterns. Brand hierarchy places Mahlkonig at premium tier ($1,310 median) for legitimate performance advantages in flat burr consistency and build quality. Bunn captures volume leadership (70 units, 28% of sales) at $190.50 median providing reliable bulk grinding for general commercial applications. Mid-tier brands (Mazzer, Ditting, Nuova Simonelli) deliver quality espresso grinding at $200-$600 range. Lesser-known brands in "Other" category (92 units, 37% of sales) create exceptional value opportunities for informed buyers at $88 median.

The value proposition spans all price tiers:

Under $100 delivers highest risk-reward ratio for buyers with technical capability. Even including $100-$300 repair costs, total investment captures functional grinders retailing $800-$2,000+.

$100-$300 tier (35% of sales) provides working bulk grinders and entry espresso units suitable for general commercial operations. Bunn and Grindmaster dominate this range delivering utility-grade performance at commodity pricing.

$300-$600 tier elevates equipment quality substantially. Mazzer espresso grinders, premium Bunn models, and well-maintained mid-tier units support revenue-generating coffee operations justifying the investment premium.

$600-$1,500 tier delivers near-certain functionality combined with equipment quality supporting serious coffee operations. Nuova Simonelli, higher-end Mazzer, entry Mahlkonig units provide professional-grade grinding at 50-70% retail discounts.

$1,500+ tier captures Mahlkonig premium models (EK43, E80 Supreme) and brand new scratch and dent units. Even at $2,000-$2,350, these represent 50-65% savings from $4,000-$6,000 retail equivalents while delivering industry-leading performance.

Critical inspection focuses on hopper condition and interlock mechanisms—the most common "does not power on" failure point. Many non-functional grinders only require proper hopper seating, creating opportunity for informed buyers. Overall equipment condition (cleanliness, general maintenance) predicts burr condition better than attempting microscopic wear assessment. Well-maintained exteriors correlate with well-maintained internals.

Brand new scratch and dent units eliminate functionality risk entirely. Cosmetic imperfections invisible in back-of-house installations translate to 40-70% discounts on guaranteed-functional equipment with new burrs and warranty eligibility. For critical operations where equipment failure stops revenue, BNSD units justify aggressive bidding up to 60-70% of retail pricing.

Technical requirements favor coffee grinders over most commercial equipment categories. Standard 120V operation eliminates electrical contractor requirements for most units. Simple plug-and-operate installation reduces deployment timeline and costs. Seasoning process (3-10 pounds cheap coffee) represents only setup complexity—minimal compared to equipment categories requiring water lines, gas connections, ventilation systems, or complex electrical service.

Parts availability determines long-term ownership success. Bunn and Grindmaster offer excellent support through general food service channels. Mazzer, Mahlkonig, and Ditting maintain strong specialty coffee supply networks. Lesser-known brands require pre-purchase research verifying parts access, but successful due diligence unlocks exceptional value.

The flat vs conical burr debate resolves through application. Serious espresso operations benefit from flat burr uniformity (Mahlkonig, premium Mazzer). Bulk operations prioritize conical burr efficiency and speed (Bunn, Grindmaster). Professional operations frequently deploy both types—flat burrs for espresso bar, conical burrs for drip coffee service.

Unlike many auction equipment categories where condition uncertainty creates risk, coffee grinders reveal operational history through visual inspection. Cleanliness, general maintenance, and component condition provide strong functionality predictions. This transparency combined with straightforward testing procedures (power on, grind test) reduces auction risk substantially.

Focus bidding efforts on recognized brands (Bunn, Mahlkonig, Mazzer, Grindmaster, Ditting, Nuova Simonelli) with confirmed parts availability. Prioritize "tested and working" designation—worth 30-50% premium over untested units. Set maximum bids before auction preventing emotional bidding destroying value propositions. Match grinder tier to operational requirements rather than purchasing capability or aesthetics. Budget for seasoning, cleaning, and potential minor service post-purchase.

With these fundamentals guiding purchasing decisions, commercial coffee grinder auctions become high-probability investments rather than gambles. The combination of essential functionality, substantial retail pricing, and deep auction discounts creates opportunity across all operational tiers.

Ready to Bid on Commercial Coffee Equipment?

PCI Auctions offers 600-900 lots weekly of restaurant and foodservice equipment including commercial coffee grinders, espresso machines, brewing systems, and complete cafe liquidations. Preview in person at our Manheim, Pennsylvania facility, inspect equipment before bidding, and leverage auction pricing for your operation.

View Current Auctions