The Commercial Range Guide 2025

The Complete Commercial Range Buyer's Guide 2025

Data-Driven Analysis of 471 Auction Sales | Expert Insights on Vulcan, Garland, Southbend, Wolf & More

The Unsung Hero: Why Ranges Determine Kitchen Success

The commercial range is the most taken-for-granted piece of equipment in any professional kitchen. No operator ever calls a tech same-day because the back left burner stopped working. No chef celebrates when all ten burners ignite properly. The dishwasher acts up? Service stops immediately. The range develops issues? The kitchen just adapts.

Back left burner hasn't worked since 1984? Use the other nine. Right oven stuck at 450°F? Perfect for finishing salmon. Left oven became permanent storage for sauté pans? That's just Tuesday. Their mechanical simplicity enables this tolerance for dysfunction. Need an ignitor? Use a lighter. Only three burners working? Adjust your station setup. The line adapts. The show goes on.

But this adaptability masks real costs. Many an owner has experienced catharsis buying a new range and watching production speed increase dramatically. Why? Everything works. You don't have to wait for poaching water to heat before making hollandaise. You can do both simultaneously. The kitchen didn't realize how much time was lost working around equipment limitations until those limitations disappeared.

Vulcan 6-burner range with integrated griddle and double oven - the versatile configuration serving restaurants for decades

Our analysis of 471 commercial range sales over 12 months reveals pricing patterns, brand performance data, and inspection intelligence unavailable elsewhere. From $50 salvage units to $8,500 brand-new scratch-and-dent installations, this guide translates auction floor experience into bidding strategy. Whether you need a basic 4-burner for a sandwich shop or a 10-burner double-oven beast for high-volume production, understanding range fundamentals prevents expensive mistakes.

Market Reality: 471 Sales Analyzed

Auction Database Overview

- Total Sales: 471 commercial ranges over 12 months

- Median Price: $215 (typical working range)

- Mean Price: $642.75 (elevated by premium BNSD units)

- Price Range: $50 to $8,500 (excluding one $31,000 food truck outlier)

- 25th Percentile: $105 (salvage/parts tier)

- 75th Percentile: $475.50 (quality working units)

The BNSD Advantage: Brand-new scratch-and-dent units command median $337.51 versus $161 for used equipment—a 2.1X premium that delivers brand-new functionality with minor cosmetic imperfections invisible in back-of-house installations.

Price Distribution by Burner Count

Burner count directly correlates with auction pricing and operational capacity. The data reveals clear tiers:

| Configuration | Units Sold | Median Price | Price Range | Typical Application |

|---|---|---|---|---|

| 2-Burner | 62 | $127.50 | $50 - $1,200 | Countertop, supplemental capacity |

| 4-Burner | 107 | $205 | $50 - $31,000 | Small cafes, limited-menu operations |

| 6-Burner | 178 | $260.50 | $50 - $6,650 | Bistros, full-service restaurants |

| 8-Burner | 11 | $231 | $56 - $2,800 | High-volume operations |

| 10-Burner | 38 | $662.50 | $51 - $8,500 | Production kitchens, large restaurants |

The 6-burner configuration dominates auction volume (178 units, 38% of market) because it represents the sweet spot for most restaurant operations. The 10-burner premium ($662.50 median versus $260.50 for 6-burner) reflects both higher capacity and the fact that 10-burner ranges typically include double ovens and premium brand construction.

Brand Performance Hierarchy

Brand reputation significantly impacts auction pricing. Premium manufacturers command consistent premiums through superior build quality, parts availability, and documented longevity:

| Brand | Units Sold | Median Price | Price Range | Tier |

|---|---|---|---|---|

| Wolf | 14 | $702.50 | $61 - $3,000 | Premium |

| Imperial | 19 | $336 | $81 - $2,750 | Workhorse |

| Vulcan | 34 | $318 | $57 - $3,450 | Premium |

| Garland | 59 | $310 | $51 - $8,500 | Premium |

| Cooking Performance Group | 48 | $285 | $50 - $3,850 | Workhorse |

| Southbend | 46 | $255.50 | $50 - $7,050 | Premium |

| American Range | 20 | $166 | $51 - $975 | Mid-Tier |

Wolf C36S-6BP premium 6-burner range - commanding $702.50 median auction price through superior construction and brand reputation

Wolf leads auction pricing ($702.50 median) through restaurant-grade construction meeting professional kitchen demands. Vulcan, Garland, and Southbend cluster in the $255-$318 range—premium manufacturers built from quality materials with well-engineered systems that outlast the restaurants they're installed in. Imperial and CPG occupy the workhorse tier, delivering solid performance at mid-market pricing. All major brands maintain adequate parts availability and serviceable designs.

Brand Selection Reality

For established manufacturers—Vulcan, Garland, Southbend, Wolf, Imperial, CPG, Montague—parts availability and service networks are adequate. These brands use similar core technology: gas from regulator passes through valves to burners. The difference lies in metallurgical characteristics, construction techniques, and classic designs that prove bulletproof over decades.

Premium brands will deliver more consistent results for longer timeframes, frequently outlasting their original installations. But all tiers work when properly maintained. The choice depends on budget, expected volume, and replacement timeline rather than absolute performance differences.

Understanding Range Configurations

Commercial ranges span numerous configurations beyond simple burner-and-oven layouts. Understanding these variations helps match equipment to operational requirements without paying for unnecessary features or lacking critical capability.

Standard Range (Burners + Oven)

The foundational configuration: open burners above, standard oven below. This represents 255 units in our database (54% of sales) with $250 median pricing. The 6-burner standard range serves as the bistro-sized workhorse appearing in most full-service restaurant kitchens.

US Range 10-burner with double oven - the backbone configuration for large production kitchens handling high-volume operations

The oven typically serves secondary functions during service. Operators use dedicated convection ovens (Blodgett or similar) for primary baking. The range oven finishes dishes—searing salmon on burners, finishing in the oven, returning to burners for a quick flambé before service. For this reason, once service starts, the range oven commonly holds at 500°F for consistent finishing timing across all dishes.

Four-burner ranges suit operations with limited range needs: sandwich shops, cafes, breakfast-focused concepts. Six-burner configurations serve most full-service restaurants. Eight and ten-burner ranges become essential for high-volume operations where multiple stations work simultaneously during rush periods.

Range + Griddle Combinations

Integrated griddle-range units command $775 median auction price—a 3.1X premium versus standard ranges ($250 median). This configuration combines burner versatility with flat-top cooking surface, eliminating the need for separate griddle equipment in space-constrained kitchens.

CPG 6-burner range with integrated 24-inch griddle and double ovens - the multi-concept kitchen solution combining burner cooking, griddle service, and baking capacity

These units excel in multi-concept operations like diners: some sautéing, some breakfast service, some cheesesteaks, a little of everything. Manufacturers use identical griddle tops as their standalone units—no quality reduction from integration. The griddle-on-left versus griddle-on-right distinction matters only if kitchen workflow design specifies particular configurations. For most installations, either arrangement functions identically.

Range + Salamander (Cheese Melter)

Ranges with integrated overhead broilers (salamanders or cheese melters) provide direct overhead heat for finishing dishes. These configurations suit operations requiring frequent broiling or cheese melting without dedicating space to standalone salamander equipment.

Garland SunFire 6-burner range with integrated salamander broiler—perfect for operations requiring frequent overhead finishing without standalone equipment

French onion soup operations love this configuration: finish with toasty, melted cheese customers expect. The salamander portion is essentially an open broiler delivering heat from above rather than all sides. These prove remarkably durable—just another gas burner pointed downward with an open-front cavity. Typical buyers include pizza shops, sandwich operations, and any concept where overhead finishing appears frequently on the menu.

Convection Oven Ranges

Ranges with convection ovens command $360 median auction price versus $250 for standard oven configurations. The convection oven's fan circulation delivers more even cooking and faster results than standard ovens. This makes them compelling for operations lacking space or budget for standalone convection ovens.

Venancio 10-burner range with double convection ovens—combining high-capacity burner cooking with professional convection baking in one footprint

The tradeoff: some dishes cannot use convection heat. Soufflés and certain cakes require still air for proper rise. For operations cooking these items, having both a standard oven and a freestanding convection oven provides flexibility. But if your menu doesn't include convection-sensitive items and space is limited, the convection range delivers excellent value.

Additional complexity is real: convection requires electric power for the fan motor even on gas ranges. But manufacturers build these robustly and fan motors rarely create operational issues. The premium pricing at auction reflects this enhanced capability.

Stock Pot Ranges

Single large burners delivering 160,000 BTU or higher serve specialized high-volume liquid cooking. These units excel at soups, stocks, demi-glace, bulk seafood steaming (crab pots), and any large-batch liquid cooking requiring rapid heating and sustained high output.

CPG 2-burner stock pot range delivering 160,000 BTU—specialized equipment for high-volume stock production and bulk liquid cooking

Despite their specialty application, stock pot ranges occupy relatively small footprints and integrate easily into most kitchens with the need. They supplement rather than replace standard ranges. Operations producing significant volumes of stocks, soups, or boiled items benefit substantially from dedicated stock pot capacity rather than tying up standard range burners for hours-long stock reduction.

Countertop Ranges

Countertop 2-burner and 4-burner units provide burner capacity without oven components or floor space requirements. These sell at $135 median auction price—roughly half the cost of comparable floor-model ranges. Despite lower pricing, countertop commercial ranges use identical design principles as floor models: gas supply through valves to burners. Just smaller scale.

Vulcan countertop 6-burner range—providing full burner capacity without floor space requirements, ideal for food trucks or chef base installations

Common applications include supplemental capacity during rush periods, catering operations, food trucks, and installation on chef bases (equipment stands). These absolutely deliver adequate performance for operations needing burner capacity without oven requirements. The construction matches commercial standards—these handle professional kitchen abuse.

Fuel Type: Gas Dominance and the Alternatives

The auction database reveals overwhelming gas preference: approximately 90% of units are natural gas or propane powered. This isn't arbitrary. Gas delivers operational advantages that make it the default choice for professional kitchens with access to gas service.

Why Gas Wins: Speed, Control, and Simplicity

Commercial gas ranges provide instant heat and instant temperature response. Turn the valve, ignite the burner, cooking begins immediately. Need to drop temperature fast before a sauce breaks? Cut the heat—temperature drops within seconds. This instant adjustment proves essential during service when timing determines dish quality.

Even the best commercial electric ranges require time for heating elements to reach temperature, then additional time for the pan to heat. Cooling follows similar delays: the element retains heat even after power cuts, continuing to transfer energy to the pan. For operations where precise temperature control determines success or failure, gas eliminates these lag periods entirely.

Flambéing dishes or burning off alcohol in reductions? Gas provides the ignition source directly. Tilt the pan, shake to release alcohol vapors, they catch the flame—instant pyrotechnics. With electric, you need the pan already at temperature sufficient to vaporize and ignite alcohol. Different technique, less control.

Commercial electric range controls—adequate for operations without gas service, but lacking the instant response and temperature precision of gas-powered units

BTU Reality Check

Most chefs don't think in BTUs. They think: "which burner boils water fastest" or "which gets the sauce bubbling quickest." BTU measurements quantify something chefs feel rather than calculate.

Commercial range burners typically deliver 20,000-30,000 BTU each. Residential burners output 5,000-15,000 BTU. That 2-3X difference translates directly to cooking speed. A 5,000 BTU difference per burner (25K versus 30K) isn't dramatic during use—you'll notice slightly different cook times, browning speeds, and boiling rates. But it's quantifiable.

For applications requiring extreme heat—wok cooking, heavy searing, rapid stock production—dedicated high-BTU equipment (wok ranges, stock pot ranges) delivers 60,000+ BTU from single burners. Standard ranges don't compete in these applications.

Electric Ranges: The Necessary Compromise

Commercial electric ranges exist for facilities without gas service. That's their primary use case. If gas lines were available, most operators would choose gas. This reality impacts auction pricing and resale markets—electric units often sell at discounts because buyer pools are smaller.

CPG 6-burner electric range—the compromise for facilities lacking gas infrastructure, delivering adequate performance with slower response times

Electric ranges add complexity: more components, more potential failure points. Heating elements burn out. Control circuitry malfunctions. Gas ranges? Regulator, valve, burner. That's the system. Mechanical simplicity equals reliability.

The power requirements create additional installation barriers. Most electric commercial ranges require 240V three-phase service for efficiency. Single-phase electric ranges exist but cost more to operate due to less efficient power delivery. The 3-phase advantage: more efficient power conversion meaning lower operating costs. A range runs many hours daily, so electric savings compound over time even if the initial three-phase infrastructure installation costs more.

Induction: The High-Tech Exception

Induction cooking represents legitimate technology advancement for specific applications. These units heat cookware directly through electromagnetic induction—the cooking surface remains cool while the pot gets scorching hot within seconds. Temperature changes are instant, matching or exceeding gas response times.

Garland induction wok range—delivering instant heat and precise control for open kitchen and demonstration cooking applications where glass-top appearance and cool cooking surfaces provide advantages

Induction wok stations work remarkably well. Personal experience: the range top stays cool, but woks positioned in concave holders for the wok bottom achieve scorching temperatures in seconds. The heat transfer to food is impressive and unlike traditional electric, temperature changes are truly instant. This makes incredible stir fry possible on induction.

The ideal applications: open kitchens, make-to-order stations, demonstration cooking, catering operations—anywhere with controlled environment and visibility. The glass-top appearance suits customer-facing applications where aesthetics matter. The cool cooking surface reduces ambient kitchen heat, valuable in exhibition cooking scenarios.

The critical limitation: fragility. One slapped pan and the glass surface shatters. For back-of-house operations where aggressive pan handling is standard, this fragility becomes prohibitive. Friday dinner rush at 6:00 PM when the kitchen is in the weeds? That's when accidents happen. And glass-top replacement costs significant money plus downtime.

Induction also requires specific cookware—magnetic materials only. Cast iron, stainless steel with magnetic properties work. Aluminum, copper, some stainless steel variations don't. This isn't prohibitively expensive (commercial induction cookware is readily available), but it adds initial investment and operational complexity.

For the right application—controlled environment, skilled operators, open kitchen presentation—induction delivers exceptional performance. For standard back-of-house high-volume operations where equipment takes abuse, gas remains the superior choice.

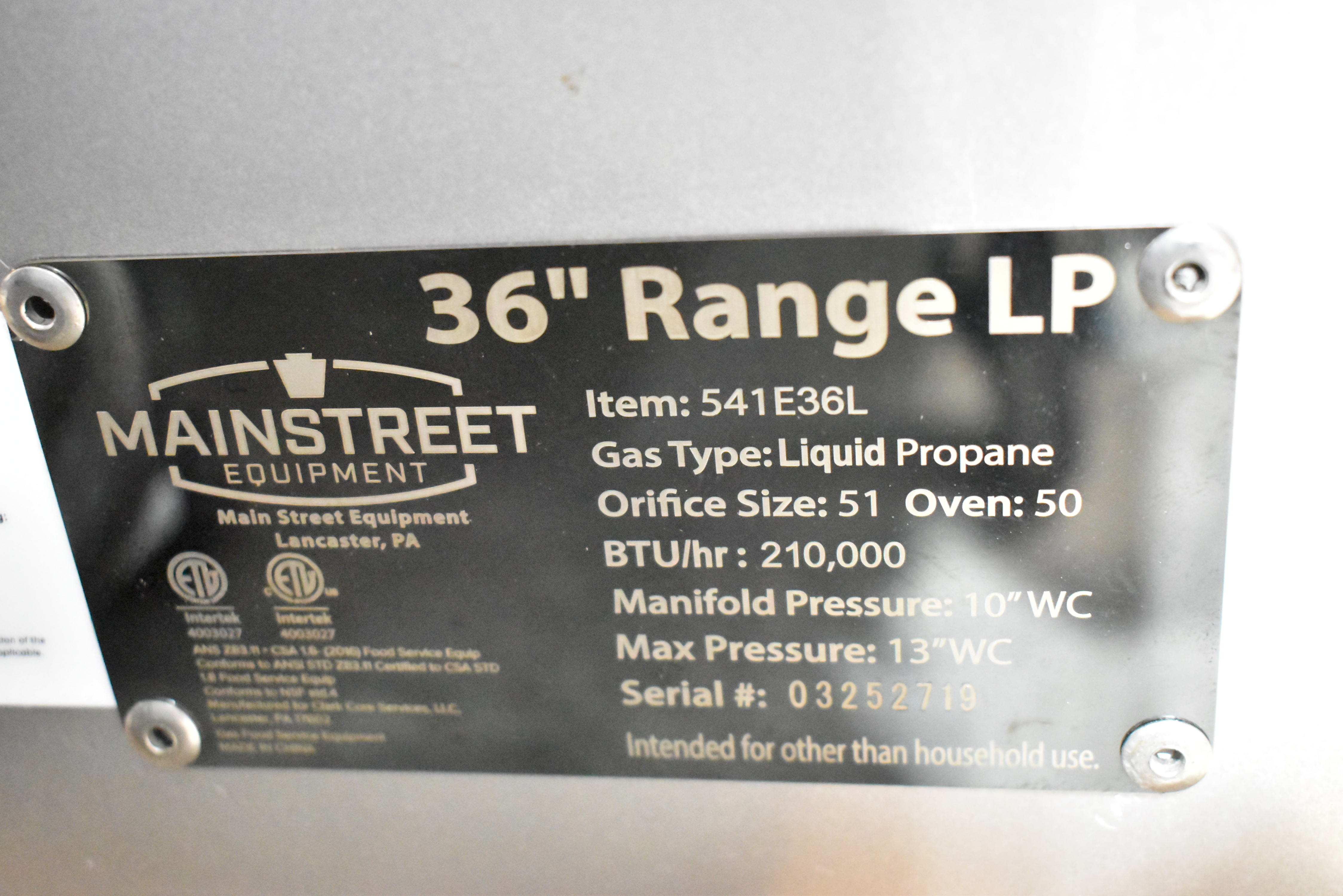

Gas Conversion: Natural Gas vs Propane

Converting ranges between natural gas and propane (LP) is remarkably straightforward on most commercial units. Many manufacturers include conversion kits with new ovens. The process involves replacing the gas regulator and swapping orifices on each burner.

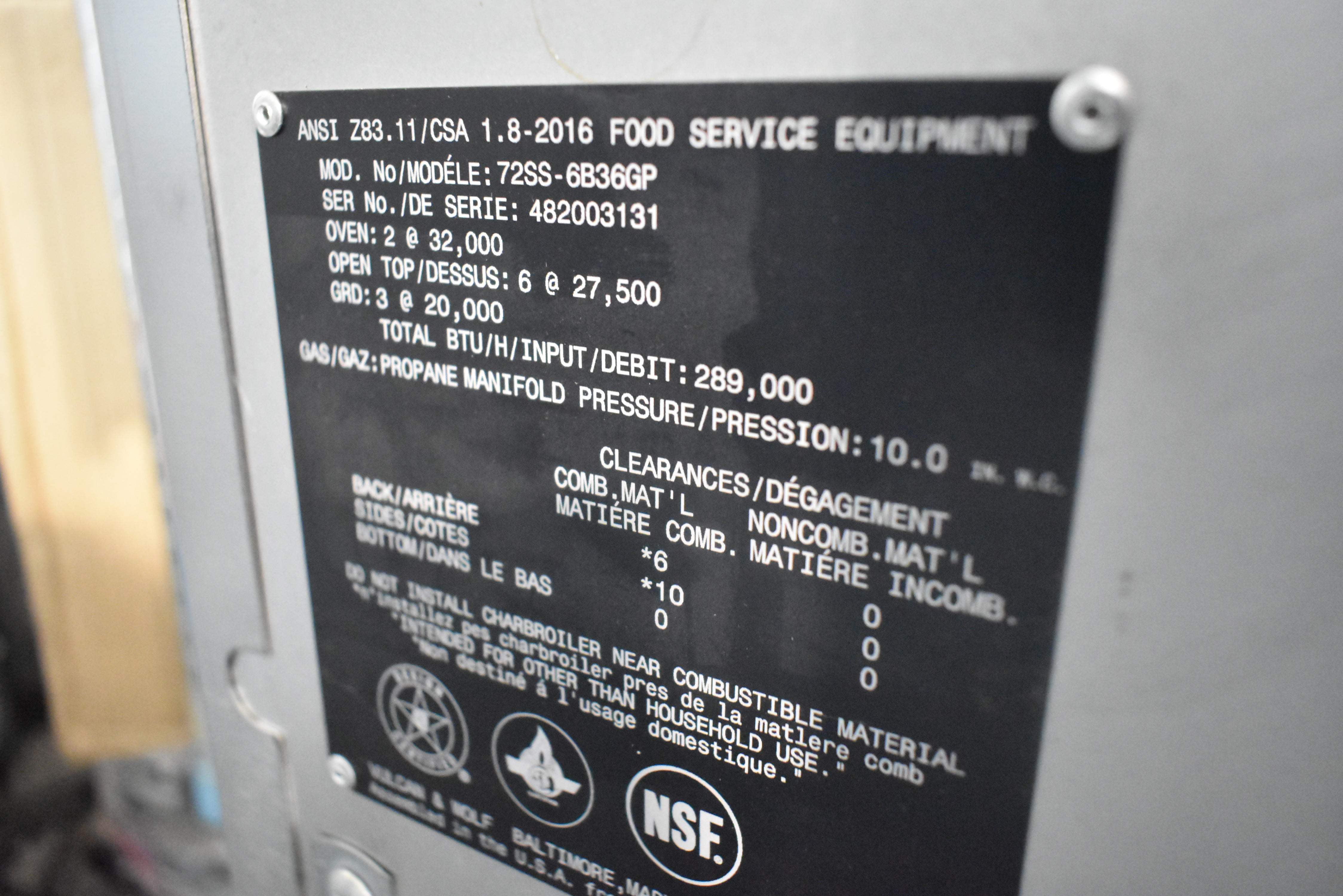

Range specification plate detailing BTU output and gas configuration—critical information for conversion planning and installation requirements

The technical difference: LP is pressurized gas (11 inches water column pressure), natural gas operates at standard pressure (3.5-7 inches water column). To deliver identical BTU output, LP requires smaller orifices than natural gas. The regulator swap adjusts supply pressure appropriately for each fuel type.

Conversion isn't complex for anyone understanding the system. It does require attention to detail: remember to convert ALL burners including ovens, salamanders, or any other flame-producing accessories attached to the range. Each flame source has an orifice that must match the gas type.

Most manufacturers sell conversion kits for their ranges. Consult manufacturer specifications for proper conversion procedures. Improper conversion affects combustion efficiency, produces incorrect BTU output, and creates safety hazards. Do it right or hire professionals.

Range burner assembly showing spider jets (candles) and flame distribution—the simple mechanical system delivering consistent heat through gas, air, and ignition

Critical Inspection Points for Auction Buyers

Commercial ranges sold at auction arrive untested in most cases. Gas units cannot be powered during preview for safety reasons (no gas connection). Visual inspection becomes the primary evaluation tool. The good news: range simplicity makes visual assessment highly reliable.

Burner Condition and Completeness

Are all burners present? Are they complete with spider assemblies (the circular or star-shaped pieces with jets/candles where flame emerges)? If yes, you're in good shape. Burner systems are remarkably robust. Unless someone has actively damaged them, they function.

Cast iron grates and burner assemblies—the durable foundation of commercial ranges that withstands decades of professional use

Many ranges appearing at auction with "back left burner doesn't work" simply have that burner disconnected from the orifice. Not broken—just disconnected. Nobody checked for seven years because they worked around it using other burners. This happens frequently. A range didn't fail; end users just never investigated minor issues.

Check spider assemblies for visible damage—bent sections, missing jets, obvious breaks. These pieces are replaceable and relatively inexpensive for major brands. But intact spiders indicate proper care and minimal abuse.

Grate Condition

Cast iron grates are the only serious choice for commercial applications. Check that all grates are present and examine for warping or cracks. Warped grates sit unevenly, causing pans to wobble during cooking. Cracked grates need replacement but this isn't prohibitively expensive—full grate sets vary by manufacturer but many are interchangeable between brands.

Missing grates often indicate salvage scenarios—someone already stripped usable parts. Complete grate sets suggest the range was removed intact from a closed operation rather than parted out.

Overall Cleanliness: The Life Story

Cleanliness tells a range's life story more reliably than any other single factor. Clean units indicate operators who maintained their equipment properly. If they invested effort in regular cleaning, they likely performed other maintenance activities: inspecting gas connections, checking burner performance, addressing minor issues before they became major problems.

Clean back splash on used range—visual evidence of proper maintenance practices that extend equipment life

Conversely, heavily soiled units with caked grease, burned carbon buildup, and general neglect suggest maintenance was deferred across all systems. This doesn't guarantee mechanical failure, but it reduces confidence in hidden component condition.

Heavily neglected range with significant carbon and grease buildup—visual indicator of deferred maintenance that may affect long-term reliability

The back splash deserves particular attention. Light accumulation is normal—kitchens are messy environments. But excessive buildup, burned carbon layers, or grease stalactites forming behind burners indicate years of cleaning neglect. This range has lived a hard life.

Moderate back splash accumulation—normal for working kitchens, showing use without neglect

Oven Functionality Assessment

Without power, assessing oven functionality relies on visual inspection and component checks. Open the oven door and examine:

- Interior condition: Clean interiors suggest proper use and care. Heavily soiled interiors with burned-on food indicate neglect.

- Racks presence: Are oven racks included? These are sometimes removed before auction. Replacement racks cost modest amounts but verify their presence.

- Burner assembly visibility: In gas ovens, you can typically see the oven burner at the bottom. Check for obvious damage or disconnection.

- Door seal condition: Many commercial range ovens don't use door gaskets because they're not required for most applications. If a gasket is present, check for tears or compression failure. But gasket absence isn't a problem—many units work perfectly without them.

Well-maintained oven interior—showing proper care and regular cleaning that extends equipment service life

Door operation: open and close the oven door several times. Does it move smoothly? Are hinges intact? Doors that bind or require forcing indicate hinge damage—repairable but worth noting for bidding purposes.

Structural Integrity

Inspect the range frame and body for damage. Commercial ranges are heavy stainless steel and cast iron construction—warping is uncommon unless someone literally dropped the unit from height. But check for:

- Rust or corrosion: Examine surfaces, underneath the burner shell, and grease trays. Iron and iron oxide (rust) combined with aluminum debris in the presence of moisture can ignite—a safety hazard. Surface rust isn't automatically disqualifying but heavy corrosion suggests water exposure or prolonged outdoor storage.

- Dents or obvious impact damage: Cosmetic dents don't affect function. Structural damage affecting gas lines, burner alignment, or oven door sealing does matter.

- Leg or caster condition: If the range has legs, are they straight? If on casters, do they roll freely? Bent legs from drop damage indicate mishandling during removal.

Commercial casters on range—critical for cleaning access, allowing the unit to be moved for behind/beside cleaning without permanent repositioning

Casters matter primarily for one reason: cleaning access. Ranges on fixed legs cannot be moved easily, allowing grease and debris accumulation behind and beside the unit. With casters, moving the range for thorough cleaning becomes routine. This cleaning capability extends equipment life by preventing grease fires and reducing pest attraction.

Control Knobs and Valves

Check that all control knobs are present and turn smoothly. Missing knobs can be replaced (universal knobs fit most valve stems), but their absence may indicate parts removal. Knobs that turn with difficulty suggest valve corrosion or damage—not necessarily a deal-breaker but worth factoring into bid price.

Range control knobs operating gas valves—simple mechanical controls that rarely fail when properly maintained

The knobs control valves throttling gas flow to individual burners. These are mechanical systems rarely requiring attention. If knobs are present and rotate freely, the valve system likely functions properly.

The Specification Plate

Every commercial range has a specification plate listing:

- Model number

- Gas type (natural gas or LP)

- Total BTU rating

- Per-burner BTU output (sometimes)

- Electrical requirements (if applicable)

- Manufacturer information

Specification plate detailing model information, gas configuration, and BTU output—essential data for installation planning and parts sourcing

This plate provides critical information for installation planning. Verify the gas type matches your facility (or budget for conversion). Note BTU requirements for gas line sizing. Record the model number for parts research if needed post-purchase.

What "Does Not Power On" Actually Means for Ranges

Unlike other commercial equipment, ranges essentially never appear at auction with "does not power on" designations. They're not electrically powered in ways that fail catastrophically (ignitors aside). Here's the reality:

Ignitor failure: This is a non-issue. Commercial range ignitors are typically small battery-powered spark generators. They click to create static spark igniting the gas. If they fail? Use a lighter or match. Restaurants do this daily. Ignitors are convenience features, not functional requirements.

Gas flow issues typically result from:

- Disconnected gas supply: Range was removed without gas connection, obviously won't function at auction preview.

- Burner disconnection: Individual burner disconnected from orifice, easy visual check.

- Valve problems: Stuck valve preventing gas flow, usually operable with penetrating oil and working the valve.

True catastrophic range failure is rare: gas leaks (dangerous, unit gets scrapped), rust-through of gas lines (extremely uncommon), structural failure rendering unit unsafe. These scenarios represent legitimate "done" status. But most ranges appearing at auction—even those looking rough—are mechanically salvageable.

The Inspection Bottom Line

If all burners are present, grates are complete, the frame is structurally sound, and the unit isn't rusted through or damaged from catastrophic mishandling, the range almost certainly works. Their mechanical simplicity is their superpower. There's very little to break: gas, valve, burner. No digital controls, no complicated routing, no finicky electronics.

Clean units from closed restaurants typically function perfectly. Dirty neglected units require cleaning and minor maintenance but usually operate. The 99.9% rule: if it's all there, it works.

Installation Requirements and Infrastructure

Commercial ranges demand substantial infrastructure beyond simple placement. Gas supply, ventilation, electrical service (for electric ranges), and space requirements all factor into total installation cost. Professional installation is strongly recommended—these aren't DIY-friendly installations.

Gas Line Requirements

Six-burner ranges typically require 3/4-inch gas line diameter. Total BTU output determines line sizing—higher BTU equipment demands larger lines or higher pressure. For natural gas, supply pressure at the range should be 3.5-7 inches water column. Propane operates at 11 inches water column.

Undersized gas lines create operational issues: all burners receive gas but don't achieve rated BTU output. Similar to wrong regulator or incorrect orifices—flame appears but full performance isn't reached. This manifests as slower heating, reduced cooking temperatures, and extended cook times. It's like running a race car on regular unleaded instead of racing fuel: it runs, but not at potential.

Natural gas is delivered via utility lines from the street. Propane requires tank installation somewhere on property with piping running to kitchen equipment. Both fuels work identically once proper pressure regulation is in place.

Ventilation: Non-Negotiable Requirement

Commercial ranges require Type I hoods (grease-rated) with adequate CFM (cubic feet per minute) airflow capacity. A general calculation: divide total range BTU by 100 to estimate required CFM. So a 6-burner range with 180,000 total BTU would need roughly 1,800 CFM hood capacity.

This is a starting point, not a precise calculation. Actual requirements vary based on:

- Duct length and configuration

- Food types being cooked

- Local fire codes

- Health department regulations

Most manufacturers include hood CFM requirements in range specifications. Follow those recommendations. Undersized hoods fail to capture grease-laden air and smoke, creating fire hazards and health department violations.

Make-up air is highly recommended even when not legally mandated. Kitchen hoods exhaust significant air volumes. Without make-up air systems bringing fresh air into the kitchen, negative pressure develops. This pushes kitchen air into dining areas (not what customers want), makes doors difficult to open, and reduces hood efficiency.

The make-up air conversation typically happens during hood installation rather than range purchase. But understand it's coming: hood costs $10,000-$25,000 depending on size, make-up air adds thousands more. Budget accordingly.

Electrical Requirements for Electric Ranges

Commercial electric ranges demand serious electrical service. Most require 240V service, commonly three-phase for efficiency. Single-phase 240V units exist but cost more to operate due to less efficient power delivery.

Three-phase power delivers electricity more efficiently than single-phase. For equipment running many hours daily like ranges, this efficiency translates to meaningful operating cost savings. The savings can offset three-phase infrastructure installation costs over months rather than years.

Not all facilities have three-phase service available. Adding it requires substantial electrical work—panel upgrades, new service entrance, possibly utility company involvement. This isn't a trivial expense. Many operators choosing electric ranges (due to gas unavailability) find three-phase installation adds thousands to the project.

If you're considering electric ranges, verify your facility's electrical capabilities before bidding. A 240V three-phase range purchased at auction for excellent pricing becomes expensive when three-phase installation costs $15,000.

Weight and Floor Loading

Six-burner ranges weigh 400-600 pounds depending on configuration. Ten-burner double-oven units approach 1,000 pounds. Flat top griddles add significant mass—roughly 200 pounds for the steel plate alone.

Floor loading rarely creates issues in commercial kitchen spaces designed for equipment. But if installing in converted residential or light commercial space, verify floor capacity. A thousand-pound range concentrated in 3-4 square feet footprint creates substantial point loading.

Casters become critical during installation for positioning and subsequent cleaning. Moving a 600-pound range on fixed legs requires multiple people and equipment. Rolling it on casters? One person can reposition it. This matters for cleaning behind and beside the unit—grease accumulation creates fire hazards and attracts pests. Regular cleaning prevents these issues, but only if the range can be moved.

Professional Installation Cost Expectations

Budget $1,000-$3,000 for professional range installation in facilities with adequate existing infrastructure (gas lines present, electrical service sufficient, hood in place). This covers:

- Final gas line connection and pressure testing

- Range positioning and leveling

- Gas leak checking all connections

- Initial test firing of all burners and ovens

- Verification of proper operation

If infrastructure upgrades are required:

- Gas line installation or upsizing: $500-$2,500

- Hood installation: $10,000-$25,000

- Make-up air system: $3,000-$10,000

- Three-phase electrical service: $5,000-$15,000

These costs dwarf the range itself in many cases. A $500 auction range becomes a $25,000 project when complete infrastructure installation is required. This is why verifying existing infrastructure before purchasing equipment is critical.

Brand New Scratch & Dent: The Premium Opportunity

Analysis of the highest-value range sales reveals a pattern: brand-new scratch-and-dent units dominate premium pricing. Eight of the top ten sales ($3,000+) are BNSD units. These ranges are cosmetically imperfect from shipping damage, warehouse handling, or minor manufacturing defects—but functionally perfect with specifications identical to showroom models.

BNSD Value Proposition

- Median BNSD Price: $337.51 vs $161 for used equipment (2.1X premium)

- Top Sale: Venancio 10-burner convection range at $7,511

- Premium Brand BNSD: Garland, Southbend, Wolf units at $3,000-$8,500

- Retail Comparison: 40-60% discount from retail pricing

- Warranty Status: Auction sales void manufacturer warranties, but BNSD units are brand new equipment

The compelling value: fully functional commercial-grade equipment at substantial discounts simply because of cosmetic damage invisible in back-of-house installations. No customer will ever see the dent in the side panel.

Brand new Southbend 10-burner double oven range—premium BNSD equipment delivering full functionality with minor cosmetic imperfections at 40-60% below retail

Major foodservice equipment distributors and manufacturers reject cosmetically imperfect units from retail channels. These units flow to auction where back-of-house buyers recognize the value proposition. Functionality is guaranteed—these are brand new ranges that failed cosmetic standards only.

Southbend 4601DD 10-burner range in original shipping crate—brand new equipment sold through auction after cosmetic rejection, delivering full commercial capability

Common BNSD damage types include dented side panels, scratched back splashes, bent legs (easily straightened), damaged packaging (unit itself is fine), or minor surface imperfections on stainless steel. These cosmetic issues don't affect cooking performance, heat distribution, or equipment longevity.

BNSD Advantages Beyond Price

Price discounts represent obvious BNSD benefits, but two additional factors make these units compelling:

Immediate Availability: Ordering new commercial ranges from manufacturers or distributors typically involves 6-12 week lead times. Equipment gets manufactured, shipped to distributor, then delivered to customer on scheduled timeline. BNSD units at auction? Available next day. Pick up the day after auction closes. For operations replacing failed equipment or opening on tight timelines, this immediate availability provides substantial value.

Brand new Garland 10-burner in two weeks from ordering? Not happening. Brand new scratch-and-dent Garland 10-burner tomorrow? Absolutely possible through auction.

Known Specifications: BNSD units are brand new, so specifications match manufacturer published data exactly. BTU ratings, gas requirements, electrical needs, dimensions—all information is current and accurate. Used equipment may have modifications, repairs, or alterations affecting specifications. BNSD eliminates this uncertainty.

BNSD Bidding Strategy

BNSD units attract competitive bidding because value is obvious—experienced buyers recognize the opportunity. This means discipline in maximum bid setting becomes critical. Getting caught in auction fever and bidding past value thresholds negates the BNSD advantage.

Research retail pricing before auction. If a comparable new range retails for $12,000, set maximum BNSD bid around $6,000 (50% of retail). This provides substantial savings while accounting for warranty loss and minor cosmetic issues. Bidding to $10,000 to "win" reduces savings to marginal levels while sacrificing warranty coverage.

The reality: another BNSD range will appear at the next auction. Supplies are consistent because manufacturers and distributors continuously generate scratch-and-dent inventory through normal shipping and warehousing operations. Walking away from one auction knowing another opportunity arrives shortly prevents overpaying through competitive heat-of-the-moment bidding.

Southbend 4601DD 10-burner with double ovens—the production kitchen workhorse available as BNSD at 40-60% retail discounts

Operational Maintenance and Longevity

Commercial ranges reward regular maintenance with decades-long service lives. Their mechanical simplicity means few components wear under normal use. Proper cleaning and periodic professional service extend equipment life well beyond initial restaurant installations—these ranges commonly outlast the businesses that buy them.

Daily Cleaning Protocols

Ranges should be broken down and cleaned daily. The top should come completely apart with no tools required: grates lift off, burner shells remove, spider assemblies pull out, grease trays slide free. This complete disassembly allows thorough cleaning of all surfaces where grease and food particles accumulate.

Parts should be soaked in degreaser solution, scrubbed, rinsed, dried, and reassembled. This 15-minute end-of-shift routine prevents carbon buildup that eventually requires aggressive chemical treatment or replacement of components. Daily maintenance is preventive. Monthly deep cleaning becomes remedial.

The back splash requires daily attention. Wipe down surfaces to remove grease spatter and food residue. This prevents layered buildup that eventually creates fire hazards when heated grease ignites. Clean back splashes also provide visual evidence of maintenance culture—operators who clean daily maintain equipment properly across all systems.

Weekly Deep Cleaning

Weekly, pull the range away from the wall (this is why casters matter). Clean behind and beside the unit where grease, food debris, and dust accumulate. This area becomes fire hazard territory when neglected—grease plus dust plus heat equals ignition risk.

Strip all burner components and soak overnight in heavy degreasing solution. Inspect spider assemblies for damage or clogs. Clean burner ports (the small holes where gas/air mixture exits and flame appears) with wire brush or pipe cleaner. Clogged ports cause uneven flame distribution affecting cooking performance.

Check oven interior for spills or debris. While ovens don't require daily cleaning like burners, weekly attention prevents buildup that eventually requires major cleaning projects. Many operators set oven to self-clean cycle (if available) weekly during slow periods.

Monthly Comprehensive Maintenance

Monthly maintenance should include complete range teardown: every burner removed, every grate soaked, every grease tray emptied and cleaned, every surface scrubbed. This prevents carbon layer formation that eventually affects heating efficiency and creates persistent odors.

Inspect all gas connections for leaks using soapy water. Bubbles indicate gas escaping—tighten connections or replace damaged fittings. This simple check prevents safety hazards and identifies problems before they worsen.

Check control valve operation. Each knob should turn smoothly through full range without binding. Stiff valves suggest corrosion or debris—address before valves seize completely. Penetrating lubricant plus working the valve usually resolves minor stiffness.

Verify oven door operation. Hinges should move freely, door should seal reasonably well (remember, many commercial ovens don't use gaskets). If door binds or requires forcing, hinge adjustment or replacement may be needed.

Annual Professional Service

Professional technician inspection and tune-up is recommended annually even when range appears to function perfectly. Technicians check:

- Gas pressure at manifold (ensures proper BTU delivery)

- All burner flame patterns (should be blue, consistent, without yellow tips)

- Oven temperature accuracy (calibration if needed)

- Gas line integrity throughout system

- Safety valve operation

- Thermocouple function (if applicable)

This service typically costs $200-$400 but catches minor issues before they become major failures. It's preventive investment rather than reactive expense.

Common Wear Items and Replacement Costs

Despite mechanical simplicity, some components wear eventually:

- Control knobs: $10-$25 each, break from physical impact (aprons catching, accidental pulling)

- Burner spiders: $30-$75 each, durable but replaceable if damaged

- Grates: $40-$120 per grate, cast iron withstands decades but cracks eventually

- Oven racks: $30-$80 each, bend from overloading or drop damage

- Door gaskets (if used): $20-$50, compress over time losing seal

- Thermocouples: $15-$40, occasionally fail in safety systems

Parts availability for major brands (Vulcan, Garland, Southbend, Wolf, Imperial, CPG) remains adequate through distributor networks and online suppliers like Parts Town and Webstaurant Store. Obscure brands or specialty equipment create sourcing challenges, but mainstream manufacturers maintain robust parts pipelines.

An important cost-saving option: purchasing parts ranges at auction. When a range sells for $50-$100, it's being bought for parts. These units provide replacement burners, grates, spiders, knobs, and other components at fraction of retail parts pricing. Operators with multiple ranges benefit from buying parts units to maintain inventory.

When Ranges Are Truly "Done"

Critical failures forcing replacement include:

- Gas leaks in manifold or main supply lines: Dangerous, not economically repairable

- Rust-through of gas delivery system: Compromises safety, replacement required

- Structural frame failure: Warping or damage affecting burner alignment or stability

- Only one working burner: Repairing multiple failed burners often costs more than replacement

These scenarios are uncommon. Most ranges appearing at auction—even rough-looking units—are mechanically salvageable through cleaning, minor repairs, and regular maintenance establishment. Their simplicity is their greatest advantage: fewer components mean fewer failure points.

Bidding Strategy by Price Tier

The 471-unit auction database reveals clear price tiers corresponding to condition, configuration, and risk levels. Understanding these tiers helps calibrate bids to acceptable risk tolerance and expected post-purchase investment.

Under $100: Parts Machines and Salvage

Units selling below $100 typically have obvious major damage, missing critical components, severe rust, or confirmed non-functionality. These are parts machines—buy them to harvest burners, grates, knobs, and other components for other equipment in your operation.

Parts-only range missing components and showing severe damage—appropriate for component harvesting but not restoration

Don't expect functional ranges at this price point. You're buying a large parts bin, not working equipment. For operators maintaining multiple ranges, these parts units provide economical component inventory.

$100-$300: The Volume Sweet Spot

This tier represents 35% of auction sales and offers excellent risk-reward ratio for experienced buyers. Units show acceptable cosmetic condition, appear complete, and likely came from closed restaurants with unknown maintenance histories but no obvious catastrophic damage.

Budget for potential cleaning, minor repairs, and professional evaluation. If you purchase at $200 and spend $500 on service, your total investment remains $700—exceptional value compared to $3,000-$8,000 retail pricing for comparable used equipment.

Used 6-burner range at $500 price point—typical condition for working units requiring cleaning and minor service

Look for units with:

- Clean or moderately soiled interiors (heavy cleaning versus complete restoration)

- Complete burner assemblies and grates

- No visible rust or structural damage

- Complete control knobs

- Intact oven doors and reasonable interior condition

These visual cues increase functionality probability even without powered testing.

$300-$500: Better Condition, Higher Confidence

This tier (15% of sales) represents cleaner units from better-maintained operations. Cosmetic condition improves, model years are more recent, and completeness is nearly guaranteed. Functionality probability increases substantially compared to sub-$300 units.

Expect minor repairs at most. This tier makes sense for buyers lacking in-house repair capability or time to troubleshoot. You're paying moderate premium for reduced risk.

$500-$1,000: Near-Certain Functionality

Units reaching this tier (12% of sales) typically work with minimal or no repairs required. You're paying premium auction pricing for reduced risk. This tier suits operations where downtime costs exceed repair savings—restaurants already open that cannot tolerate week-long equipment outages.

These units often include:

- Recent model years (less than 5 years old)

- Excellent cosmetic condition

- Brand names with strong resale value

- Desirable configurations (convection ovens, griddle combinations)

$1,000-$3,000: Low Hours, Recent Models

This tier (8% of sales) consists of nearly-new equipment from failed restaurants, lease returns, or high-end models from premium operations. Condition approaches retail quality. Competition includes equipment dealers and restaurant supply companies—stay disciplined on maximum bids.

Verify the premium is justified by comparing to retail pricing. A $2,500 auction range should retail for $6,000+ to represent genuine value. Otherwise you're paying dealer pricing at auction without dealer service or warranty.

$3,000-$8,500: Brand New Scratch & Dent Territory

This tier represents BNSD units and premium equipment in exceptional condition. These purchases eliminate functionality risk entirely while delivering 40-60% retail savings. Competition is fierce because value is obvious to all bidders.

Set maximum bids based on retail pricing research and maintain discipline. A BNSD Garland 10-burner retailing at $12,000 makes sense at $6,000 auction price. At $10,000? The savings don't justify warranty loss and cosmetic compromise.

The Bidding Discipline Requirement

Auction fever is real. Competitive bidding creates emotional investment overriding rational pricing. Combat this by setting maximum bids before auction starts. Write them down. Commit to walking away when bidding exceeds your threshold.

Another range will appear next week. PCI runs 600-900 lots weekly including regular range inventory. Missing one auction knowing consistent supply exists prevents overpaying through competitive heat-of-the-moment decisions.

Final Assessment: The Neglected Hero Deserves Attention

Commercial ranges occupy the paradoxical position of being simultaneously essential and ignored. No equipment matters more to daily kitchen function. No equipment receives less attention when operational issues develop. This tolerance for dysfunction stems from their mechanical simplicity: basic systems continue functioning even when degraded.

But this adaptability masks real costs. Kitchens working around equipment limitations lose production speed, compromise dish timing, and frustrate staff forced to compensate for malfunctioning equipment. The moment a new range enters service—everything working, every burner responding, both ovens holding temperature—operators realize how much time was wasted on workarounds.

Value Proposition Summary

- Median auction price: $215 vs retail $3,000-$12,000+

- Best risk-reward tier: $100-$300 (35% of market)

- Premium BNSD tier: $3,000-$8,500 (40-60% off retail)

- Top brands: Wolf ($702.50 median), Vulcan ($318), Garland ($310), Southbend ($255.50)

- Service life: Decades with proper maintenance, outlasting original installations

The auction market rewards strategic thinking. With 471+ units available annually and median prices around $215, supply consistently exceeds demand. Smart buyers focus on matching equipment to operational requirements rather than winning individual auctions.

Gas dominates for good reason: instant heat response, precise temperature control, mechanical simplicity. Electric ranges serve facilities without gas access but sacrifice operational advantages. Induction represents legitimate advancement for specific applications but lacks durability for standard back-of-house abuse.

Brand selection matters less than condition and configuration appropriateness. Wolf, Vulcan, Garland, and Southbend command premiums through superior construction, but all major brands deliver adequate performance when properly maintained. The difference appears over decades, not days.

Critical inspection focuses on completeness and cleanliness. If burners are present, grates complete, frame structurally sound, and rust/corrosion absent, the range almost certainly works. Clean units from well-maintained operations deserve premium bids because care translates to reliability.

Installation requires professional expertise. Budget $1,000-$3,000 for professional installation plus any required building infrastructure upgrades. Ventilation is non-negotiable—Type I hoods with adequate CFM capacity prevent fire hazards and health department violations. Make-up air improves kitchen comfort and hood efficiency even when not legally mandated.

BNSD units represent lowest-risk auction purchases. Brand-new functionality at 40-60% retail savings with only cosmetic compromise invisible in back-of-house installations. The immediate availability (next-day pickup) provides substantial value over 6-12 week manufacturer lead times.

There is a lot to consider when replacing the unsung hero of your line: the range. Talk to your team, your chefs, your line cooks. Discuss what's going to be the most efficient, best choice for your workflow. By getting dynamic input from your team, you'll make an educated and well-informed buying decision that will serve as the heart of your kitchen for years to come.

The range determines whether your kitchen functions efficiently or forces staff to adapt around equipment limitations. This fundamental reality makes range selection critically important despite the equipment's tendency to be overlooked and underappreciated. Give your kitchen the tools it deserves.

Ready to Bid on Commercial Restaurant Equipment?

PCI Auctions offers 600-900 lots weekly of restaurant and foodservice equipment including commercial ranges, refrigeration, cooking equipment, and complete restaurant liquidations. Preview in person at our Manheim, Pennsylvania facility, inspect equipment before bidding, and leverage auction pricing for your operation.

View Current Auctions